In early 2025, XinHai Mining received a letter of gratitude from the client of the Zimbabwean spodumene project, expressing sincere thanks to the XinHai team for their tenacity and hard work during the project's construction and production.

Customer Thank You Letter

From 2022 to 2023, Xinhai Mining provided a full range of EPC services for the 2 million TPY spodumene processing project in Zimbabwe, helping the development of China's lithium ore new energy industry. The project took only 364 days from start-up to commissioning. The Xinhai EPC services content covers the entire process of mineral processing flow design and research, equipment manufacturing and procurement, and plant construction and installation. Against the backdrop of rapid fluctuations in lithium product prices, Xinhai Mining raced against time to ensure that the project was delivered on time, setting an example for Chinese companies in the construction of overseas mining projects.

Use the table of contents below to navigate through the guide:

01Project construction timeline

| Date | Event |

|---|

| June 2022 | Sign project contract |

| July 2022 | Conduct mineral selection test |

| July 2022 | Start construction work |

| September 2022 | Confirm process plan |

| September 2022 | Manufacture production equipment |

| March-April 2023 | Install and debug equipment |

| June 2023 | Successful equipment trial operation |

| July 2023 | Official trial production |

| September 2023 | Ship refined lithium ore powder back to the country |

| November 2023 | Completion and commissioning ceremony |

02Project background

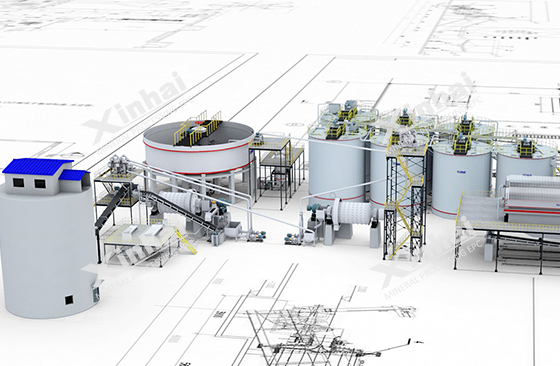

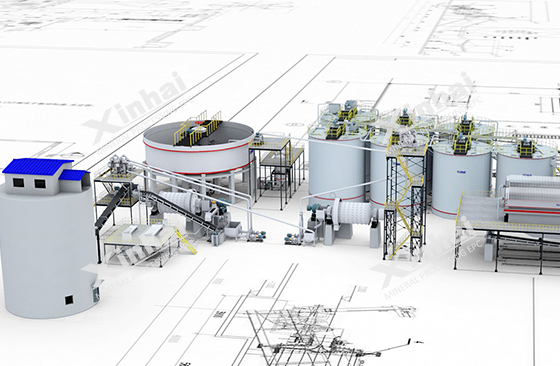

(Aerial view of the project)

In the primary stage of project construction, the new energy market has risen rapidly, the lithium mining industry has a strong momentum of development, and major companies have seized the opportunities in the lithium battery new energy market. In April 2021, the customer visited Xinhai Mining for the first time for a visit and inspection. The two sides conducted in-depth technical exchanges and discussions on all aspects of the spodumene EPC general contracting project.

After an in-depth understanding of many mining EPC general contractors, the customer was impressed by Xinhai Mining's professional EPC services and its commitment to on-time production. Finally, in early June 2022, the customer chose Xinhai Mining as the EPC general contractor for the 2 million TPY spodumene processing project in Zimbabwe.

03Project Overview

Ore properties: The ore is mainly spodumene, followed by petalite, containing very small amounts of lepidolite, as well as associated tantalum, niobium, beryllium, rubidium, and cesium.

Process flow: crushing and screening - grinding and classification - weak magnetic separation - desludging - lepidolite flotation - spodumene flotation recovery - concentrate dehydration - tailings concentration and discharge.

Finished product: spodumene concentrate.

04Xinhai Solution

E- Design and Research

1. Ore dressing test:

Xinhai Mining adopts innovative thinking to conduct mineral beneficiation tests. In view of the properties of the lithium ore in this project, Xinhai Mining and Mineral Processing Research Institute has established a special lithium ore test and pilot research center to conduct lithium ore process mineralogy research and customize targeted beneficiation process flow.

Recovery of lepidolite (containing rubidium and lithium):

Xinhai Mining adopts lithium ore flotation process, and obtains lepidolite (containing rubidium and lithium) and spodumene concentrate through desludging - magnetic separation - flotation process to obtain lepidolite and spodumene in sequence. During flotation process, lepidolite (containing rubidium and cesium) minerals can be floated out first due to their good floatability, which is convenient for improving the grade of spodumene concentrate in subsequent flotation process and ensuring its concentrate quality.

Since the lithium ore of this project contains a lot of mud, if desludging is not performed, it will have many adverse effects on the flotation process: first, the mud will absorb a large amount of reagents, resulting in a significant increase in reagent consumption; second, the slurry will become viscous, deteriorating the aeration conditions; in addition, the mud is easy to cover the surface of the coarse-grained ore, affecting the flotation effect, and may be mixed in the foam product, thereby reducing the concentrate grade. Therefore, Xinhai added a cyclone desludging link in the mineral processing process. After desludging, the flotation effect is significantly improved.

Flotation of spodumene concentrate:

It adopts a closed-circuit process of one roughing, three sweeping and three concentrating for spodumene flotation. The mineralization of reagents has a significant impact on the flotation effect of spodumene. Xinhai Mining has taken the following measures to ensure the flotation effect.

✦ High-efficiency and powerful stirring tanks are used to fully ensure the stirring and circulation effect of reagent mineralization.

✦ There are many types of flotation reagents, and there is a sequence of addition, so a longer mineralization time is required. Xinhai Mining uses multiple high-efficiency and powerful agitation tanks in series to ensure the mineralization time of reagents, thereby ensuring the flotation effect.

✦ Spodumene flotation foam is large and easy to occupy the flotation time. Xinhai Mining appropriately extends the flotation time.

✦ Spodumene flotation foam is sticky and easy to block the foam tank. Xinhai Mining appropriately reduces the number of operating tanks.

2. Ore dressing process design:

In the early stage of the dressing plant construction, Xinhai Mining Design Institute sent technical experts to the site for many times to investigate the ore resources, surrounding terrain, water sources, power supply and other conditions, assisted customers in collecting and integrating various resource information, and combined with the process flow recommended by the ore beneficiation test to select optimal equipment and carefully design construction drawings, providing customers with professional and comprehensive planning in terms of site selection, design, construction, etc.

P- Manufacturing and procurement

Xinhai Mining Machinery Design Institute has configured a coarse crushing workshop, a medium and fine crushing workshop, a screening workshop, a powder ore bin, a grinding workshop, a flotation workshop, a gravity separation workshop, a lithium mica concentrate dehydration system, a spodumene concentrate dehydration system, a tailings dehydration and a reagent workshop for the project, and also customized a complete set of main and auxiliary equipment.

In terms of equipment manufacturing and procurement for lithium mining projects, Xinhai Mining strictly controls quality, down to every link of processing and manufacturing, from raw materials to finished products, all of which must undergo strict quality control and inspection to ensure that the products meet high standards and can adapt to foreign site conditions, so as to provide efficient and reliable lithium mining production lines.

C- Civil Engineering and Installation

The 2 million TPA spodumene project in Zimbabwe is a large cross-regional and cross-cultural cooperation project. It also brings considerable challenges to Xinhai Mining in terms of civil construction and equipment installation. The strict project completion time also puts forward higher requirements for the progress management, staffing, technical support, supply, food and transportation of EPC general contracting projects.

Xinhai Mining has rich project experience in Zimbabwe. The construction and installation and commissioning team has more than 20 years of practical experience and is familiar with local conditions, which can avoid most construction problems. The Planning and Accounting Department, the Engineering Project Department, and the Installation and Commissioning Department make timely adjustments according to the time schedule to ensure that the installation and commissioning are completed on time with quality and quantity, lock in the cost for the entire project, and improve the benefits!

05Project Highlights

Mining General Contractor! Tailor-made with Innovative Thinking

"Optimal solutions for your mines", Xinhai Mining provides tailor-made EPC general contracting services for the 2 million TPA spodumene project in Zimbabwe, using innovative thinking to design and construct the entire process.

After analyzing the experimental results, Xinhai Mining found that petalite is an important recycling product in the Zimbabwe project, but at that time there was no successful production practice case of heavy medium separation and selection of petalite in China, nor was there a heavy medium hydrocyclone that met the requirements.

To this end, Xinhai Mining and Mineral Processing Research Institute has established a special lithium ore test and pilot research center and built a petalite heavy medium test and pilot research device. Experimental research was conducted on the appropriate particle size, feed pressure, heavy medium specific gravity, various structures and parameters of the cyclone, etc. The experiment proved that in the lithium ore of this project, petalite accounts for 20.31% of the entire lithium mineral, the petalite concentrate grade is 3.8%, and the annual production of 50,000 tons of petalite concentrate can be achieved.

Create a record! Completed and put into production smoothly in one year

Zimbabwe is located south of the equator, with only two seasons a year: dry and rainy. The construction period of Xinhai Mining's lithium mine project coincided with the rainy season, which brought problems and challenges to the construction. The entire Xinhai Mining team adhered to the service tenet of on-time production. The Zimbabwe 2 million TPA spodumene project was successfully put into trial production in just one year! It not only created the Xinhai speed, helped customers to start production during the high period of lithium ore prices, but also created a new model for project construction in the global mining industry!

In terms of personnel organization, Xinhai Mining has formulated a strict construction plan. The Zimbabwe project team has selected managers with rich experience to be responsible for on-site construction, installation and commissioning. During the peak period of project construction, Xinhai Mining dispatched a construction and installation team consisting of up to 423 Chinese employees and nearly 600 local employees, working day and night and working together to promote project construction.

In terms of material organization, due to the lack of commercial concrete in Zimbabwe, the prices of cement, sand and gravel are relatively high. Xinhai Mining has specially invested in and shipped mobile integral frame stone crushing stations, small concrete mixing stations, pump trucks, truck cranes and other construction machinery and equipment for the Zimbabwe spodumene project site to assist in the project construction. At the same time, more than 90% of the platforms and supports in the plant use modular steel structures, which are bolted and installed with labor-saving and labor-saving methods, greatly improving civil engineering efficiency, shortening civil engineering construction period and saving infrastructure investment.

Management escort! Cumulative shipments of about 170 million pieces

During the project construction, Xinhai Mining's strong manufacturing capabilities provided a solid guarantee for the smooth construction of the project. Xinhai Mining has passed multiple international quality certifications and has Canadian CWB welding qualifications. The intelligent high-end equipment production center can produce more than 1,000 products used in mining, selection, and smelting, and can provide a full set of main and auxiliary equipment for mine production below 50,000 tons/day.

From September to December 2022, Xinhai Mining relied on a scientific and rigorous packaging and shipping system, using waterproof wrapping, stretch film, pallets, wooden boxes and other forms to avoid collisions, wear, corrosion and other possible damage during transportation; reasonable space design and cargo unloading design to reduce transportation and unloading costs; using the numbering and manual management system to ensure that equipment and spare parts are complete, reduce the difficulty of equipment installation, and safely and non-destructively ship a total of about 170 million pieces, providing strong support for the smooth progress of the project and further ensuring the project schedule.

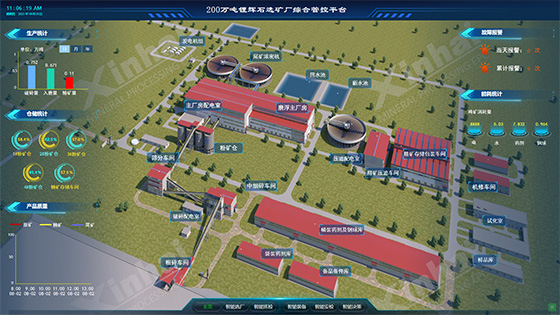

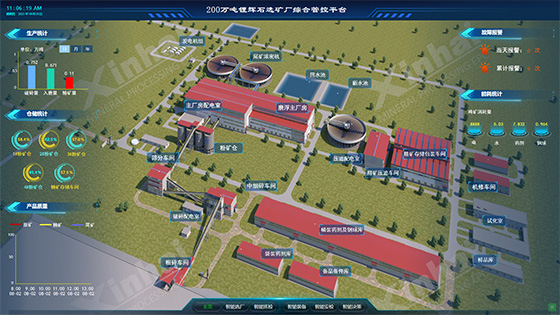

Smart concentrator! Overall automation solution

Xinhai Mining adheres to the construction principle of "unified planning-cooperative design-stage construction-synchronous debugging-operation improvement", and customizes the overall planning of intelligent mines and the whole process automation system of the concentrator for customers, improves the production efficiency of lithium ore concentrators, reduces production costs, and helps customers build smart mines and green mines.

Among them, the automated management and control system includes functional modules such as homepage, smart concentrator, smart equipment, smart decision-making, smart inspection, and smart security inspection. On the one hand, the online production data is realized, which is convenient for the centralized control of the concentrator equipment and effectively improves the efficiency of mine management; on the other hand, the workshops such as crushing, grinding, and pumping stations can be unmanned, and the form of centralized control + smart inspection is adopted to reduce personnel allocation, reduce labor, reduce potential factors of safety accidents in the factory area, and improve production safety.

People-oriented! Chinese-style garden living and office area

During the design and construction of the 2 million TPA spodumene project in Zimbabwe, Xinhai Mining adhered to the "people-oriented" design concept and designed a unique Chinese-style garden-style office and living area for the project. The office area is decorated with high-end elements, creating an elegant and atmospheric office environment and working atmosphere. The living area is designed with winding paths, ponds, rockery and other elements to create a quiet and comfortable working atmosphere. Mining workers can relax here after work and enjoy the natural beauty and pleasant atmosphere. This not only helps to improve the work efficiency and quality of life of mining workers, but also demonstrates Xinhai Mining's care for mining workers and the inheritance of Chinese traditional culture.

06Project Results

On November 29, 2023, the completion and commissioning ceremony of the 2 million TPA spodumene project in Zimbabwe was held! Zimbabwean President Mnangagwa, Zimbabwean Vice President Chiwenga, Zimbabwean Minister of Mines Suda, and the project leader attended the event and delivered speeches respectively, congratulating the commissioning of the lithium mine project. The President of Zimbabwe visited the 2 million TPA spodumene flotation plant built by Xinhai Mining Equipment on site and personally pressed the commissioning button in the central control room.

Since the commissioning, all equipment has been working normally, the entire process flow is smooth and stable, and various technical production indicators have far exceeded expectations. The lithium mine project customer said: "The project has been one of the models of Chinese overseas mining from feasibility study, design, equipment supply, civil construction, installation and commissioning to reaching the standard and production capacity to the later production and operation management."

The 2 million TPA spodumene project in Zimbabwe undertaken by Xinhai Mining has witnessed the remarkable achievements of the China-Africa lithium mining project and is a milestone record in China's mining technology level and manufacturing capabilities. Xinhai Mining's EPC general contracting service provides solid technical and equipment support for the construction of the 2 million TPA spodumene project in Zimbabwe. In the future, Xinhai Mining will continue to focus on the design and construction of green mines and smart mines, and strive to make greater contributions to the construction of new energy and new quality productivity in the country and the world.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE