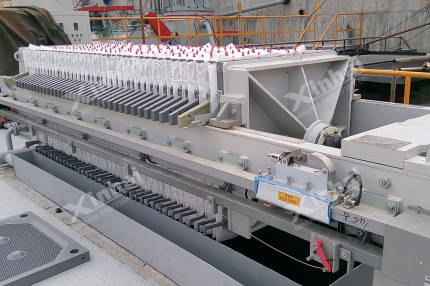

Filter plate immersed in the pulp while in operation produces a surface absorption of filter cake, with the action of capillarity and integrated with the vacuum pressure. The filtrate enters the distributing valve and drainage tank through the filter plate. Filter cake comes out from the slime hopper receiving spray washing. Filter cake falls into the tank by the pressure from the wind and scraper.

It can be used for floating and dewatering in clean coal and fine materials like tailings, and it can be also used in metallurgy, chemical, petroleum, sewage treatment, and other aspects of the solid-liquid separation.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE