Xinhai has a complete packaging and shipping management system, capable of handling large-scale project shipments worth billions. Taking the Zimbabwe 2 MTPA Lithium Mine Project as an example, the cumulative shipment volume of the project was 170 million pieces. The entire packaging and shipping work were carried out methodically, with no omissions, mistakes, or damages, providing strong support for the smooth implementation of the EPCM+O work and fully demonstrating Xinhai's professional capabilities and efficient execution in large project shipment management.

01

Complete Packaging and Shipping Management System

To ensure that equipment arrives at the project site undamaged, Xinhai has developed a comprehensive packaging and shipping management system. This system uses various packaging forms such as waterproof wrapping, stretch film, pallets, wooden boxes, cartons, bags, naked packaging, bundling, and containers to avoid damage during transportation, such as collisions, abrasion, and corrosion. Through meticulous space design and cargo unloading design, transportation and unloading costs are effectively reduced. Xinhai also implements a numbering and instruction manual management system to ensure the integrity of equipment and spare parts, reducing equipment installation difficulty.

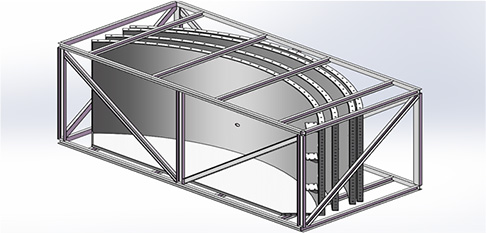

In the packaging stage, Xinhai has formed a professional team of mechanical process engineers, beneficiation engineers, electrical automation engineers, industrial design engineers, inspection and customs declaration personnel, and warehousing personnel. This team summarizes the dimensions, shapes, weights, moisture-proof, and lifting requirements of the packaged items, considering handling, disassembly, and transfer transportation, as well as the position of on-site installation. After computerized simulation processing, they classify and package the items.

02

Thoughtful and Detailed Packaging and Shipping Services

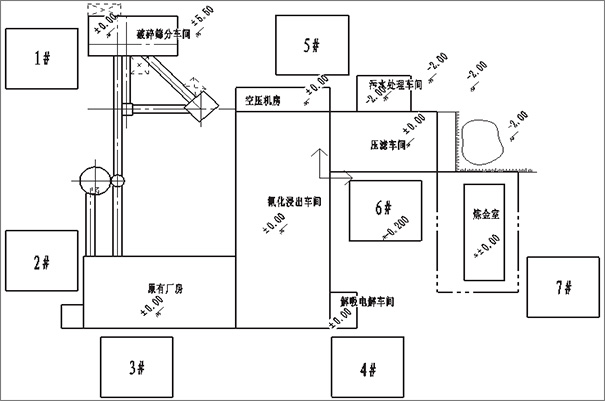

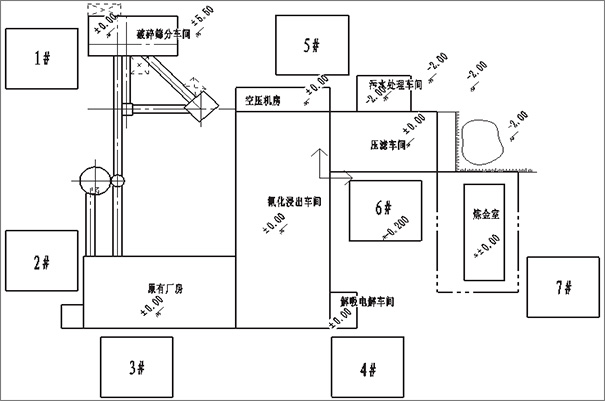

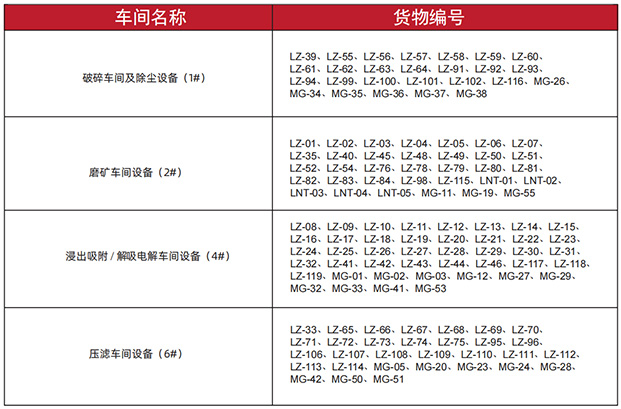

Through meticulous space design and cargo unloading design, Xinhai effectively reduces transportation and unloading costs. In terms of packaging design and shipping design, based on the overall layout of the construction site, Xinhai determines the loading area for each work area and formulates precise unloading positions, avoiding the inconvenience of secondary handling and lifting, and facilitating site management and improving installation work efficiency.

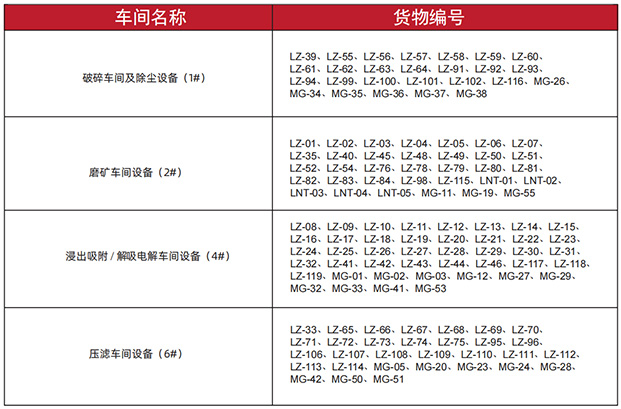

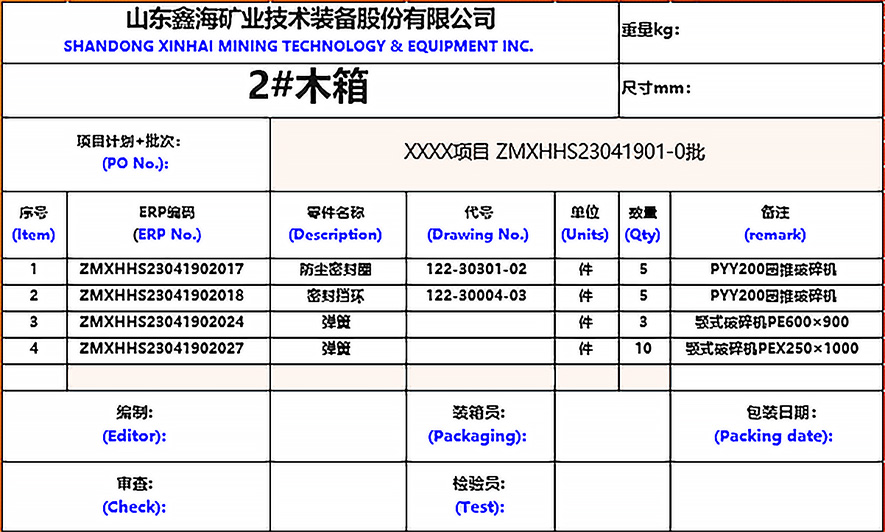

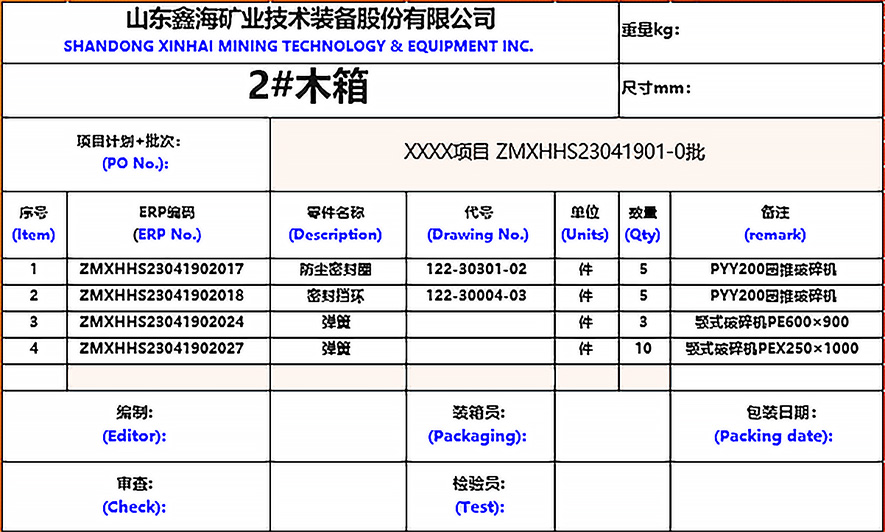

Xinhai also implements a numbering and instruction manual management system to ensure the integrity of equipment and spare parts, reducing equipment installation difficulty. To quickly locate goods during installation and reduce the workload of lifting and handling on-site, Xinhai numbers various goods containers or large naked packages, requiring the goods to be unloaded at designated locations at the mine site. This not only facilitates handling and lifting but also makes it easier to locate the goods.

-

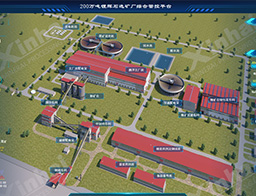

Unloading Planning and Designated Location Map

-

Unloading Numbering and Container, Wooden Box, etc. Numbering Table

03

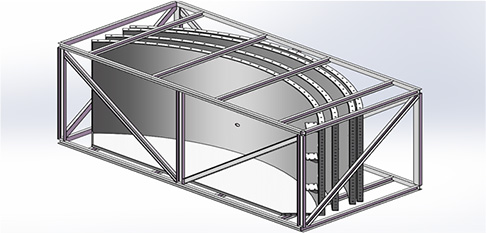

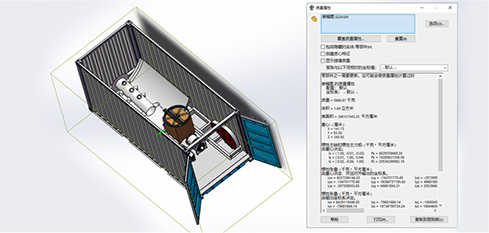

Professional Digital Packaging and Shipping Process

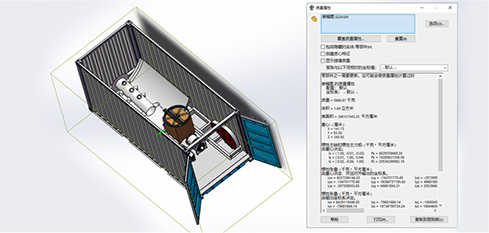

Xinhai has a fist-class packaging and shipping center, where the entire process from packaging planning, design to implementation, as well as overall packaging and shipping, is managed digitally and scientifically. Xinhai uses advanced ERP and WMS systems to achieve 3D visualization of packaging status and container status, as well as digital processing of packaging information. In the logistics process, Xinhai uses barcode technology for efficient scanning. Before the product is shipped, Xinhai attaches barcodes to the equipment and packaging boxes to ensure the orderly shipment of large quantities of items. This also allows project sites to quickly identify and store goods, facilitating subsequent installation work. This measure greatly improves logistics efficiency and accuracy, ensuring the smooth progress of the project.

-

Packaging Status 3D Visualization

-

Packaging Status 3D Visualization

Packaging Information Digitization

Xinhai deeply understands that the management of the packaging and shipping process is crucial for the smooth progress of the project. Any negligence may result in loss or damage of items or difficulties during unloading, storage, and installation on-site, even requiring secondary handling. Therefore, Xinhai always strictly controls this process to ensure that all items can be delivered to the project site intact, safely, and orderly, meeting project needs and ensuring smooth project progress.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080