With the continued exploitation of global copper resources, the mining and utilization of low-grade copper oxide ores has received increasing attention. Research shows that copper resources in low-grade copper oxide ores account for about 20% of total copper reserves. However, as the ore grade decreases year by year, the number of difficult-to-treat copper oxide ores continues to increase. If not utilized rationally, it will cause a serious waste of resources. Therefore, the research and development of processing technology for low-grade copper oxide ores has become an important issue in the mining industry.

Use the table of contents below to navigate through the guide:

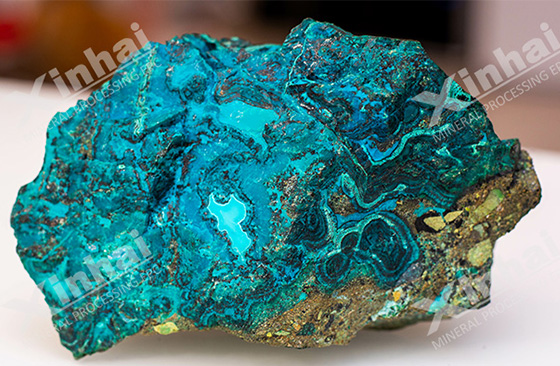

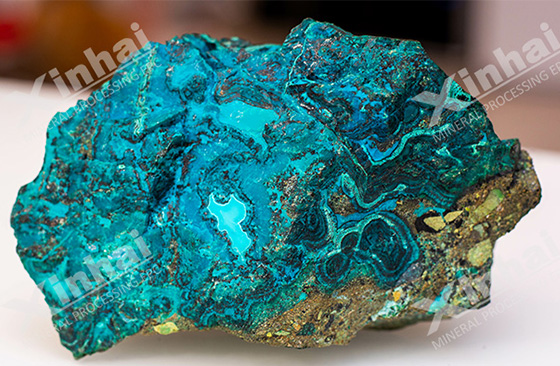

01Characteristics of low-grade oxidized copper ores

Low-grade oxidized copper ores usually have the following characteristics:

1. High oxidation rate: The oxidation rate in oxidized copper ores is generally high, which makes copper recovery more difficult.

2. High content of bound oxidized copper: The content of bound oxidized copper in the ore is usually high, making it difficult to effectively extract it with traditional beneficiation and smelting technology.

3. Fine-grained and impregnated: The mineral particles are fine and the dissemination is complex, which increases the challenges in the beneficiation process.

4. High mud content: The ore contains a lot of mud, which affects the efficiency of beneficiation and smelting.

5. Polymetallic symbiosis: Copper ores often coexist with other metal minerals, further complicating the processing process.

Due to the above characteristics, traditional beneficiation and smelting technologies are difficult to meet the processing needs of low-grade oxidized copper ores, which has prompted the mining industry to increase research and technology development in this field.

02Overview of low-grade copper oxide ores treatment process

At present, the methods for treating low-grade copper oxide ore mainly include separation-flotation, acid leaching and ammonia leaching.

1. Separation-flotation method

Separation-flotation method is an effective treatment technology, and the main steps include:

- Grinding ore: Grinding ore to a certain particle size to improve the efficiency of subsequent treatment.

- Adding halide and reducing agent: Converting metal into volatile halide by roasting, and using reducing agent to precipitate it on the surface of carbon particles.

- Flotation enrichment: Further separation and concentration of the separated product by flotation technology.

Separation-flotation method is suitable for treating ores with high mud content and high content of combined copper oxide. Although its technical and economic indicators are good, the investment and production costs are high, and the operation control requirements are strict.

2. Acid leaching

Acid leaching is the main method for treating copper oxide ores, and dilute sulfuric acid is usually used as the leaching agent. According to the characteristics of the ore body, the acid leaching method can be further divided into percolation leaching and stirring leaching.

2.1 Percolation leaching

This method is suitable for coarse-grained ores, including heap leaching, in-situ leaching and tank leaching:

- Heap leaching: low-grade ore and residual ore are piled together and leached using natural precipitation. The advantages are low investment and low cost, but the leaching cycle is long and the leaching rate is low.

- In-situ leaching: leaching is carried out in situ in the ore, and the leaching solution is sent into the ore body through the injection hole, which simplifies the equipment and cost, but there is also the problem of long leaching cycle.

- Tank leaching: dilute sulfuric acid is sprayed in the prepared leaching tank. The equipment is simple, but the labor intensity is high and the leaching efficiency is low.

2.2 Agitation leaching

Agitation leaching is a mature process for treating copper oxide ores. It is a process that mixes finely ground ore particles with acid solution to allow them to fully contact and improve dissolution efficiency. Although this method is highly efficient, it has high investment and energy consumption.

3. Ammonia leaching method

Ammonia leaching method is suitable for treating copper ore with a large amount of alkaline gangue and high mud content. By adding ammonia leaching agent (such as (NH4)2CO3 or (NH4)2SO4), ammonia can slowly leach copper minerals and form copper-ammonia complexes. This method avoids the high acid consumption and high impurity problems of acid leaching when treating high alkaline gangue.

The main methods of ammonia leaching include pressurized ammonia leaching and reduction roasting-normal pressure ammonia leaching, which can improve the recovery rate of copper under certain conditions.

The treatment of low-grade copper oxide ores is an important challenge faced by the mining industry. Xinhai Mining provides customers with professional solutions with rich experience and advanced technology. By rationally utilizing low-grade oxidized copper ore resources, we can effectively deal with the problem of resource shortage and achieve sustainable utilization of resources. Xinhai Mining looks forward to working with you to explore the infinite possibilities in the field of copper ore dressing.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE