Copper ore is one of the important minerals and is widely used in various industries. With the gradual reduction of high-grade and high-quality copper ore resources, it is necessary to continuously improve and optimize the copper ore dressing process to improve the utilization rate of copper ore resources. Since there are many types of copper ores in nature, such as malachite, chalcocite, bornite, etc., the selection of copper ore dressing process should be based on the specific ore type and characteristics. Common copper ore dressing technologies include: flotation, gravity separation, leaching and combined dressing. Efficient dressing equipment is another important factor in improving the efficiency of copper ore dressing. Xinhai Mining has been committed to copper ore dressing for more than 20 years and has completed the design and construction of multiple copper ore dressing plants. The following will introduce you to copper ore dressing technology, equipment and Xinhai Mining's successful cases to help you better understand copper ore dressing.

Copper Ore Beneficiation Technology

Flotation Technology

The principle of copper ore flotation is to utilize the physical and chemical properties differences between copper minerals and other impurity minerals, and to combine copper minerals with foam by adding appropriate flotation agents and foaming agents, thereby separating them from other impurity minerals. Specifically, the flotation agent can generate a layer of hydrophobic substances on the surface of the copper mineral, while the foaming agent can make the foam have sufficient stability and adsorption, thereby achieving the purpose of effective separation during the flotation process.

Modern copper ore flotation reagents involve many kinds of reagents, including collectors, foam stabilizers, regulators, dispersants, potions, etc. New flotation reagents can change the surface properties and chemical properties of minerals, thereby achieving the purpose of improving flotation recovery.

Applicable minerals: refractory copper oxide ores, copper sulfide ores, mixed copper ores and complex copper-containing ores

Copper Ore Processing Equipment

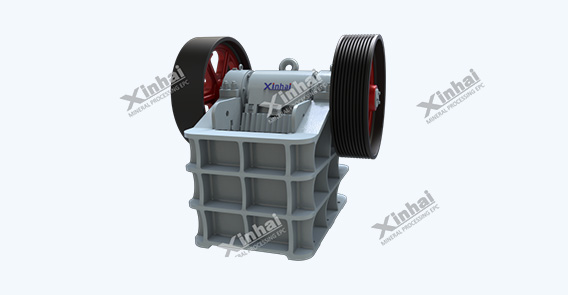

Crushing stage

There are many kinds of crushing equipment in xinhai, jaw crusher and cone crusher are often used in copper ore crushing process.

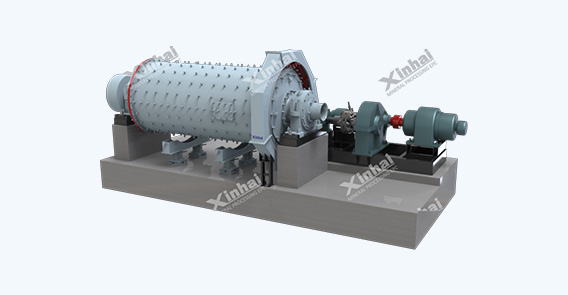

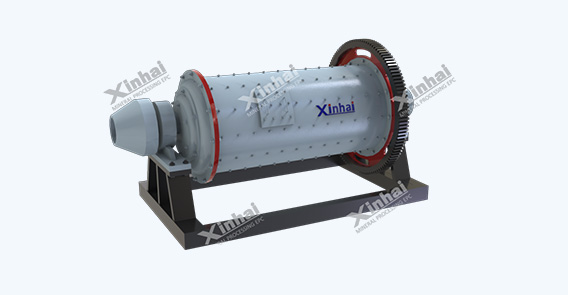

Grinding Stage

Classifying Stage

Xinhai has successfully produced the leading high-efficient hydrocyclone in the world, which can be combined with each other for adapting to different process requirements. The thickening and dewatering efficiency was up to 80% ~ 90%; At the same time, the hydrocyclone was lined with Xinhai wear-resistant rubber that extended service life of 2-4 times.

Beneficiation Stage

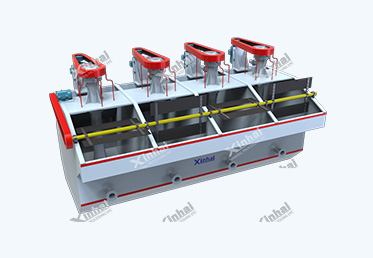

Flotation Machine

Flotation Machine

Dewatering Stage

Thickener

As the world's leading thickener manufacturer, Xinhai has successfully developed various types of rake, deep cone and tilted plate thickeners, covering a free settling range of 20-3500㎡, fully meeting the needs of various ores and different scales of production.

Filter Machine

Xinhai has developed and improved various types of filters and dewatering screens, fully ensuring that the concentration of concentrate and tailings meets the standards. The moisture content of concentrate can be reduced from the original 45-60% to 10-18%, and has successfully applied for a number of national patents.

Xinhai Mining Copper Ore Dressing Plant Cases

CASE 1

Pakistan 1,500t/d Copper Mineral Processing Plant

Xinhai solution

Two-and half-stage closed-circuit crushing - one-stage closed-circuit grinding - flotation process of one-stage roughing, two-stage scavenging and two-stage concentration - two-stage mechanical dewatering

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080