From June 18th to 20th, the 2024 China Graphite Industry Chain Development Conference was held in Qingdao, Shandong. The conference was organized by the China Non-metallic Mineral Industry Association with the theme of "Transformation and Upgrading, Cost Reduction and Efficiency Improvement, and Innovative Development". Xinhai Mining participated in the conference with EPC+M+O Service, analyzed the current situation and trends of our country's graphite industry with the elites of upstream and downstream enterprises present, and discussed the development prospects of the graphite industry.

(Xinhai Mining booth)

Li Hong, director of Xinhai Mine Design Institute, delivered a speech on "Sharing the Experience of Foreign Large Flake Graphite Ore EPC Ore Dressing Technology" at the forum, demonstrating Xinhai Mining's strength in technological innovation and project construction in the field of graphite beneficiation!

(Speech by Li Hong, director of the Mine Design Institute)

2024 is the year of striving to develop new quality productivity. As a strategic resource in the fields of new energy, new materials and high technology, graphite has good application prospects. Graphite materials are widely used in battery negative electrode materials. With the rapid growth of new energy vehicles and lithium-ion battery markets, the demand for graphite is also rising. Xinhai Mining will continue to accelerate the breakthrough of graphite beneficiation technology innovation, accumulate experience in graphite beneficiation project construction, improve the graphite beneficiation full industry chain service, and enhance Xinhai Mining's core competitiveness in graphite beneficiation services!

Use the table of contents below to navigate through the guide:

01Innovative graphite beneficiation test

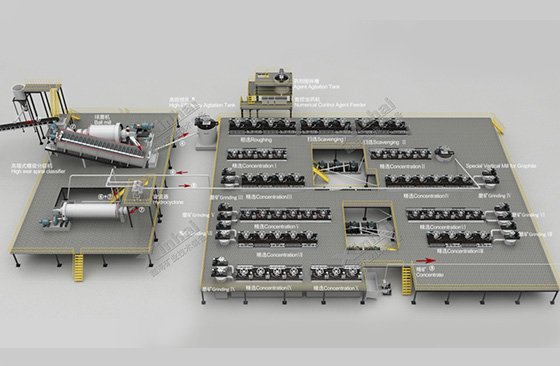

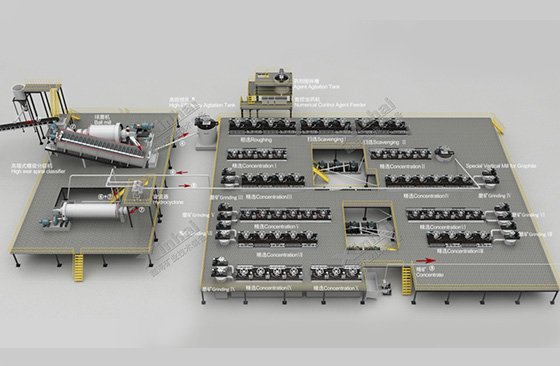

(Xinhai Mining Graphite Beneficiation Process)

Xinhai Mining Research Institute has accumulated rich experience in graphite beneficiation. It fully considers the ore characteristics of each mine and adopts innovative thinking to formulate test plans for each ore sample. It can provide a variety of purification processes such as flotation, gravity separation, electrostatic separation, selective flocculation, alkali acid, acid leaching, chlorination roasting and high temperature roasting. In the graphite beneficiation process, Xinhai Mining pays great attention to protecting the crystal structure of graphite, especially the integrity of large flakes. In the beneficiation test, multi-stage grinding, multiple separations, coarse concentrate re-grinding and re-selection process are often used to protect the graphite flake structure while maintaining a high recovery rate.

02Customized graphite concentrator design

(Xinhai Mining Graphite Project)

Xinhai Mining has Class B design qualification in the metallurgical industry, with 14 departments, 16 majors, and more than 80 professional design talents in geology, mining, mining machinery, well construction, ore dressing, civil engineering, electricity, water supply and drainage, heating, ventilation, tailings, pipelines, automation, steel structure, technical economy and budget estimation, etc., to carry out professional data collection and feasibility studies, and provide graphite concentrator design and construction design solutions.

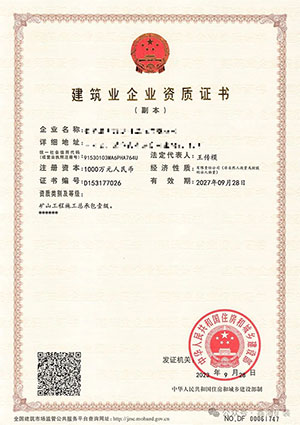

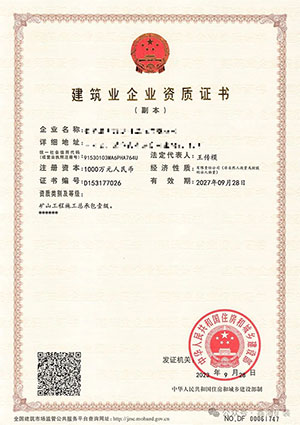

(Xinhai Mining Mine Engineering Construction General Contracting First-Class Qualification Certificate)

In addition, Xinhai Mining has Class I qualification for general contracting of mine engineering construction, and can strictly carry out civil construction work for customers in accordance with the established design plan.

03High-efficiency graphite beneficiation equipment

Xinhai Mining has been focusing on the research and development of beneficiation equipment for more than 20 years. It has two major production plants and more than 200 skilled beneficiation equipment manufacturing workers. The new intelligent equipment manufacturing workshop is equipped with automatic welding operators, various types of vertical lathes, gear hobbing machines and other processing equipment. According to customer needs, various types of equipment required for graphite beneficiation can be customized. Graphite beneficiation equipment mainly includes vertical stirring mills for graphite, flotation machines, drum dryers, reagent stirring tanks, chamber filter presses, XHGY-B series CNC dosing machines, etc.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE