Copper flotation reagents are chemicals used in the process of separating copper minerals from gangue minerals and other minerals. The goal of copper flotation is to concentrate copper minerals into a marketable copper concentrate, which can then be further processed to extract pure copper metal. Various reagents are used in copper flotation to achieve efficient separation. Commonly used copper flotation reagents include collectors, frothers, modifiers and dispersants. The following will introduce these four kinds of flotation reagents.

Use the table of contents below to navigate through the guide:

01Copper ore flotation collector

Collectors are surface active chemicals that selectively bind to copper minerals, making them hydrophobic. This helps them to attach to the air bubbles introduced in the flotation cell. Commonly used copper collectors include xanthate and phosphine disulfide.

1. Xanthates: including ethyl acetate xanthate, pentyl xanthate, etc. They are the most commonly used copper flotation collectors and adsorb on the surface of copper minerals, making them hydrophobic, which encourages them to bind to air bubbles.

2.Phosphine disulfides: including diethylene phosphine disulfide and diisobutyl phosphine disulfide. They are also commonly used copper flotation collectors with a similar mechanism of action to effectively float copper minerals out.

02Copper ore flotation foaming agent

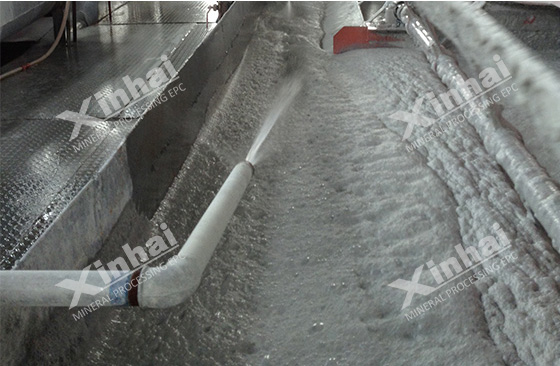

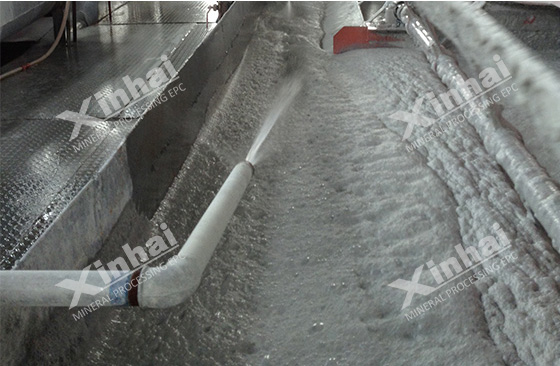

The foaming agent is added to the flotation equipment to form a stable and long-lasting foam on the surface of the tank. This froth brings hydrophobic copper minerals to the top of the flotation cell, where they can then be removed. Commonly used blowing agents include retinol, methyl isobutyl alcohol and polyether based blowing agents.

1. Rosin oil: Rosin oil is a commonly used foaming agent, which can form stable foam in the flotation cell and bring hydrophobic copper minerals to the liquid surface of the flotation cell.

2. Methyl isobutyl alcohol: Methyl isobutyl alcohol is a common foaming agent, which has good foaming performance and stability, and can improve the flotation efficiency of copper minerals.

3. Polyether-based foaming agent: In copper flotation, foaming agents based on polyether compounds, such as polyethylene glycol and polypropylene glycol, can also be used. These frothers are able to form long-lasting froth and provide good flotation performance during the flotation process.

03Copper ore flotation modifier

Modifiers are agents added to adjust the pH and chemical conditions of the flotation slurry to optimize copper recovery. Common modifiers include conditioners (such as lime or sulfuric acid), inhibitors, and activators.

1. pH regulator: The pH regulator is used to control the pH of the flotation slurry to optimize the flotation performance of copper minerals. Commonly used pH regulators include lime (CaO), sodium hydroxide (NaOH), sulfuric acid (H2SO4), etc. They can increase or decrease the pH value of the flotation slurry to suit different copper mineral flotation requirements.

2. Inhibitors: Inhibitors are used to suppress minerals that do not need flotation to improve the selective flotation of copper minerals. Common inhibitors include cyanide (such as sodium cyanide), iron sulfate (FeSO4), etc. They can inhibit the flotation of other minerals in the flotation process to increase the recovery rate of copper minerals.

3. Activator: Activator is used to enhance the flotation performance of specific copper minerals. Depending on the specific copper ore type, different activators may be used. For example, for copper sulfide ores, commonly used activators include copper sulfate (CuSO4) and sodium sulfide (Na2S), etc.

04Copper ore flotation dispersant

Dispersants are used in the copper flotation process to improve the dispersion state of reagents and solid particles in the flotation slurry to ensure effective contact between copper minerals and flotation reagents. The following are some commonly used copper flotation agent dispersants:

1. Polyacrylamide: Polyacrylamide is a commonly used dispersant, which can effectively improve the dispersion of flotation slurry, reduce the aggregation of solid particles, and thus improve the flotation efficiency of copper minerals.

2. Epoxy resin: Epoxy resin has good dispersibility and adhesion, and can be used as a dispersant to help evenly disperse the flotation agent in the flotation slurry and enhance the dispersion state of solid particles.

3. Polyethylene glycol: Polyethylene glycol is a compound with excellent dispersibility and can be used as a dispersant to help maintain the uniform dispersion state of agents and solid particles in the flotation slurry.

The above content is the introduction of copper ore flotation collectors, foaming agents, modifiers and dispersants. The selection and dosage of these flotation reagents mainly depend on the specific copper ore properties, flotation process and operation requirements. Different ore types and flotation processes require different combinations of flotation reagents. In order to improve the flotation effect of copper ore, it is necessary to conduct mineral processing test analysis on the ore to determine the appropriate combination of copper ore flotation reagents.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE