According to statistics, 85% of the world's metal mines - including copper,

iron, lead, and zinc mines - are mined using open-pit mining. While people enjoy

the benefits brought by open-pit mining, there are also concerns about its

large-scale land destruction and ecological impact. This article introduces the

definition, process flow, advantages, and disadvantages of open-pit mining.

Use the table of contents below to navigate through the guide:

01What is open pit mining?

Open-pit mining is a method of extracting ore in an open space by stripping

off the surface covering layer according to the occurrence conditions of the ore

deposit, using specific mechanical equipment. It is suitable for ore deposits

with shallow ore bodies, large scales, and thin covering layers.

02Pros of open pit mining

1. Full utilization of resources

Open-pit mining maximizes the useful value of the ore body. On the one hand,

because the entire ore body is directly exposed and high-precision sorting

equipment is used, the ore recovery rate can be increased to 90%–98%. On the

other hand, due to the large operational surface area of open-pit mining, both

the main ore species and associated elements can be recovered simultaneously,

further enhancing resource utilization.

2. Low ore loss and dilution

Open-pit mining enables true full-view extraction. The boundaries of the

mining area can be accurately controlled using a GPS slope monitoring system,

with an error margin within 0.5 meters. As a result, the ore loss rate is only

3%–8%.

During the mining process, the degree of waste rock mixing is low, resulting

in minimal ore dilution. Taking copper ore as an example, for every 1%

reduction in the dilution rate, the ore dressing cost decreases by

0.8%–1.5%.

3. Large production capacity

Take iron ore as an example: the annual production capacity of a single

open-pit mine reaches 50–100 million tons, which is 10–15 times greater than

that of underground mining. This is because the large mining area allows 50–100

medium-sized pieces of equipment to operate simultaneously. In addition, a

continuous operation system can further increase production capacity by 30%.

4. High production safety

Open-pit mining has no risk of confined space, which can avoid mining

accidents caused by gas explosions, water seepage accidents and ground pressure

disasters. In addition, visual management and mechanization instead of manual

operation are also important factors in improving production safety.

03Cons of open pit mining

Ecological Environmental Damage

Open pit mining covers a vast area, with a single pit often spanning tens of

square kilometers. Vegetation destruction and soil erosion during the mining

process also lead to significant ecological damage.

Economic Cost

Efforts are being made to repair the environmental damage caused by open-pit

mining; however, these efforts come at a huge economic cost. The cost of

post-mining land reclamation is approximately $100,000–$150,000 per hectare, and

water resource restoration projects can require investments of around $1

billion.

04Open pit mining process

1.Planning and Design

Planning and design are based on geological exploration data, combined with

the ore demand from downstream production processes. They are carried out in

accordance with the principles of technical feasibility, economic efficiency,

safety and reliability, and the full utilization of resources.

2.Mine Construction

The process of mine construction includes: surface clearing and stripping →

mining platform construction → ore transportation road construction → spoil dump

construction → construction of other auxiliary facilities.

3.Ore Mining

Drilling and blasting: Large drilling equipment is used to drill a series of

blast holes on the bench surface according to predetermined hole pattern

parameters. After completing the charging, stemming, and wiring work, blasting

is carried out in accordance with safety regulations. The ore and rock fragments

produced by the blasting are piled at the bottom of the bench to form a blast

pile.

Mining and Loading:Move excavators or loaders to the blast

pile and load the broken ore and rock into transportation equipment.

Transportation:The transportation equipment hauls the loaded

ore and rock from the mining face to the unloading point in continuous

round-trip operations.

Dumping:The large amount of topsoil and waste rock generated

during mining needs to be piled up in a planned manner. Dump sites are usually

selected in valleys, depressions, or specially designated areas near the mining

zone.

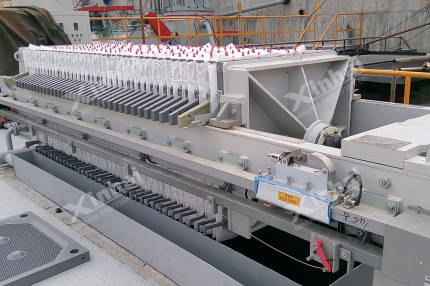

05Xinhai Open-Pit Mining: Building an Intelligent Mine

With the advancement of science and technology, intelligent mining has become

a prevailing trend. Xinhai Mining actively drives the development of intelligent

mines by integrating cutting-edge technologies such as 5G communications, big

data analysis, AI algorithms, IoT, and remote sensing detection into a

comprehensive system.

In open-pit mining, the intelligent truck dispatch system optimizes

transportation routes, while remote-controlled shovel loading enables unmanned

operations. Automatic hole layout technology enhances blasting accuracy. The 3D

visualization management platform integrates data across the entire mine,

enabling dynamic monitoring of the production process. The intelligent dispatch

system boosts mining efficiency while reducing safety risks and operational

costs.

Slope monitoring technology, including total station measurement, GPS

monitoring, and radar monitoring, allows for real-time tracking of slope

deformation. During mining, the slope angle should be carefully designed based

on the rock nature and geological structure to ensure stability. If signs of

instability appear, timely reinforcement and slope cutting measures should be

taken to prevent collapses.

Considering environmental protection, Xinhai integrates environmental and

sustainable development requirements in the planning, design, and production

stages of open-pit mining, using advanced technologies and management practices

to promote the balanced development of resource extraction and environmental

protection.

As an open-pit mining contractor, Xinhai Mining boasts advanced design

concepts, intelligent mining equipment, and an experienced construction team,

enabling the creation of low-cost, high-yield mining projects for customers.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE