Copper flotation is an important mineral processing process in the development of copper resources. Different types of copper ores will have different flotation methods and technology choices due to differences in their ore composition and physical properties. By rationally adjusting the selection of crushing, grinding, slurry adjustment and flotation reagents, the recovery rate of copper minerals and concentrate quality can be significantly improved. The following will introduce you to the characteristics of the flotation process of copper sulfide and copper oxide, preliminary preparations for flotation, and selection of flotation reagents to help you better understand copper flotation.

Use the table of contents below to navigate through the guide:

01Flotation technology of different copper ores

Sulfide copper ores flotation

The efficiency of the flotation process of copper sulfide ore is largely related to the particle size distribution of the ore, the particle size of the mineral embedding and the physical and chemical properties of the mineral surface. When the copper sulfide ore particle size is too fine, ore separation is more difficult, and too fine ore particle size will cause the loss of copper ores. Therefore, when processing copper sulfide ore, the crushing and grinding processes need to be carefully controlled to ensure the best flotation state. In the flotation process of copper sulfide ore, suitable collectors can be effectively adsorbed on the surface of copper sulfide minerals to form a hydrophobic film, promote the combination of minerals and bubbles, and achieve the separation of target minerals from gangue minerals. In actual production, the use of xanthate collectors can effectively improve the recovery rate and concentrate grade of copper.

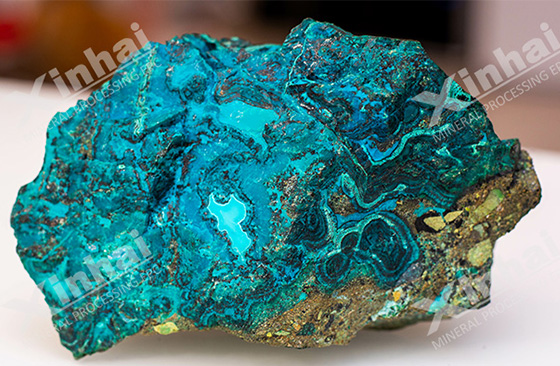

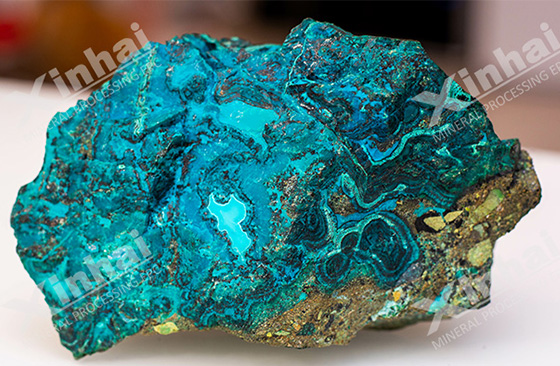

Flotation process of oxidized copper ores

Oxidized copper ore is mainly composed of malachite, azurite, chrysocolla and other minerals. These minerals are relatively complex, so the flotation of oxidized copper ore is more difficult than that of sulfide copper ore. The flotation of oxidized copper ores requires more precise adjustment of the pulp and pH value to ensure that the collector and frother can effectively act on the mineral surface. When the pulp pH value is around 9-10, the flotation effect of oxidized copper ore is best. However, the flotation of oxidized copper ore needs to be optimized according to the composition and characteristics of the ore to achieve effective recovery of copper ore resources.

02Preliminary preparation for copper ores flotation

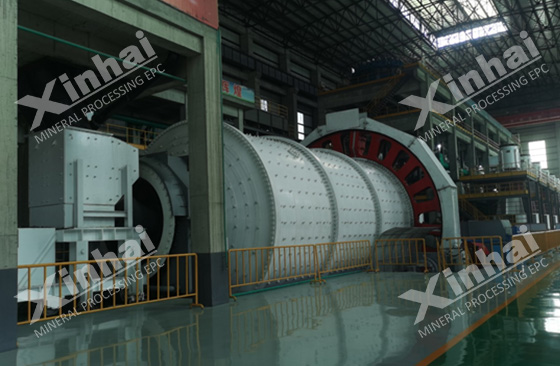

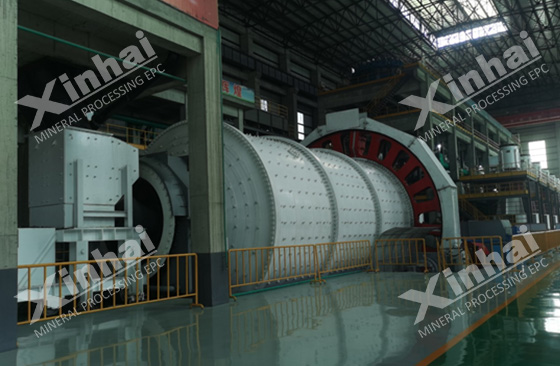

Crushing and grinding of copper ores

Crushing and grinding will directly affect the efficiency and effect of subsequent copper flotation. Crushing is to crush large pieces of copper ore into smaller particles for subsequent grinding operations, while grinding is to grind the crushed copper ore into a particle size suitable for flotation. When processing sulfide copper ore, fine grinding can enhance the activity of the mineral surface, thereby improving the adsorption efficiency of the collector. In actual production, the selection of grinding and fine grinding needs to comprehensively consider the properties of the copper ore, the type of flotation reagents and the performance of the flotation equipment.

Copper ores slurry adjustment

In the copper flotation process, slurry adjustment directly affects the flotation efficiency and the final copper concentrate quality. Slurry adjustment mainly includes slurry concentration, temperature, pH value and flotation reagent addition. Slurry concentration generally needs to be controlled within a certain range, and the solid content is generally 25%-40% to ensure that the mineral particles can fully contact the flotation reagent. Because temperature affects the solubility and reaction rate of the reagent, temperature control is also crucial. Usually, the slurry temperature needs to be controlled at 20-30 degrees Celsius. The adjustment of slurry pH value needs to be based on the type of ore and the characteristics of the reagent used. The slurry pH value of copper sulfide ore flotation needs to be adjusted to 8-11.

In addition, during the slurry adjustment process, it is also necessary to consider adding an appropriate amount of dispersant or flocculation to improve the fluidity of the slurry and the dispersion state of the mineral particles. By adjusting these aspects, the selectivity and recovery rate of copper ore flotation can be significantly improved, thereby improving the utilization efficiency of copper ore resources.

03Types and selection of copper ores flotation reagents

Collectors: The commonly used collectors for copper sulfide ore flotation are xanthates (butyl xanthate or isopentyl xanthate). These agents will form a hydrophobic surface on the surface of copper sulfide minerals, improving the flotation effect of the minerals. Fatty acid collectors (oleic acid and its salts) are often used for the flotation of oxidized copper ores. These collectors will form stable salts with the surface of oxidized copper ores under alkaline conditions, enhancing the hydrophobicity of the minerals. In actual production, the type and selection of collectors need to be optimized according to the properties of the copper ore and the flotation conditions.

Frothing agent: The selection of a suitable frother needs to consider the properties of the copper ores, the flotation reagent system, the pH value of the pulp, and the type of flotation equipment. For the flotation of copper sulfide ores, frothers such as pine oil and methyl isobutyl carbinol (MIBC) can be selected. These frothers can effectively reduce the surface tension of bubbles and increase the carrying capacity of bubbles, thereby improving the grade and recovery rate of copper concentrate. In actual production, the amount of frother needs to be precisely controlled, otherwise it will have an adverse effect on the flotation effect.

In summary, copper ores flotation processes vary depending on the type of ore. Scientific design of the process and control of parameters are the key to improving copper recovery and concentrate grade. With the continuous advancement of technology, copper flotation technology will be further optimized, which can not only improve the utilization efficiency of copper resources, but also reduce the impact on the environment.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE