From the perspective of mineral processing technology, in addition to weakly magnetic iron ore, the types of iron ore also include magnetite, mixed iron ore and multi-metal symbiotic composite iron ore. Among them, the beneficiation of magnet ore is a process with a unique process flow. Magnet minerals are found in almost all types of iron ore deposits. The ore usually called magnetite means that the content of magnetic iron in the ore is more than 85%. This type of ore can be sorted using a single magnetic separation method, which can achieve higher technical and economic indicators. The process flow of the magnetite ore dressing plant has the following salient features:

Use the table of contents below to navigate through the guide:

01Pre-selection process in crushing and screening process

During the mining process, the raw ore will inevitably be mixed with a certain amount of surrounding rock, especially in underground mining, the surrounding rock mixing rate generally reaches 15% to 20%. For underground mines that adopt the pillarless sublevel caving mining method, the surrounding rock mixing rate may exceed 20%, thereby reducing the grade of the selected ore. In order to restore the geological grade, save energy consumption for ore dressing, and reduce the amount of grinding, some magnetic separation plants at home and abroad have adopted pre-selection technology in the crushing and screening process through new construction or technical transformation in recent years. For example, the surrounding rock is discarded using magnetic pulley dry separation technology, which is usually carried out after medium or fine crushing, and some are discarded after coarse crushing. This method effectively improves the grade of the ore and reduces the difficulty of subsequent processing.

02"More crushing and less grinding" in ore dressing plant

Crushing operations account for an important part of production costs and infrastructure investment, and the energy consumption of grinding is even more significant. Therefore, most mineral processing plants adopt the strategy of “more crushing and less grinding”, that is, reducing grinding operations through multi-stage crushing to reduce total energy consumption. In recent years, in order to reduce grinding energy consumption and improve production efficiency, most ore dressing plants have adopted a multi-stage closed-circuit crushing process based on the maximum block size of raw ore, and adjusted the ratio of coarse, medium and fine crushers.

03Adopt stage grinding and ore dressing process

The two-stage grinding and stage separation process is often used in the ore dressing plant. A dewatering tank or a dewatering tank plus a magnetic separator is set between the first and second stage grinding operations. The main purpose is to discard the gangue that has been dissociated into monomers. After the coarse concentrate is secondary classified, the precipitated minerals are returned for secondary grinding, and the overflow part is obtained by magnetic separation to obtain concentrate and tailings. When processing unevenly embedded poor magnetite ore, after the first stage of rough grinding, the ore can be discarded after magnetic separation. When using a spiral chute to process such ores, coarser monomer dissociation qualified concentrates can also be selected, and the remaining materials enter the second stage of grinding. This process can reduce the number of secondary grinding machines and save more than 50% of energy and ball consumption.

04Continuously update magnetic separation equipment

With the development of science and technology, the replacement of magnetic separation equipment has become the key to improving ore dressing efficiency. The application of fine screening and regrinding technology can further improve the sorting effect and product quality. For example, by introducing new high-efficiency magnetic separators and fine screening equipment, effective sorting can be performed within a finer particle size range, thereby improving the overall mineral processing efficiency.

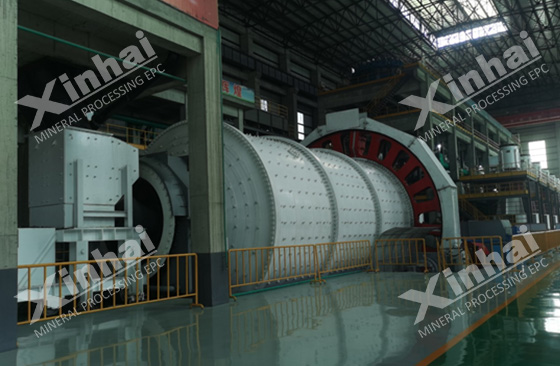

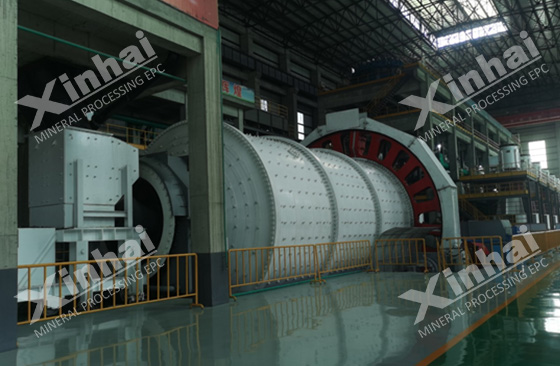

05Application of semi-autogenous grinding technology

Traditional fully autogenous grinding has the problems of low grinding efficiency and high energy consumption. In order to improve the production capacity of the autogenous mill, the following three technical measures are mainly applied at this stage:

1. Add steel balls that account for 4% to 15% of the volume of the autogenous mill, and change the fully autogenous mill to semi-autogenous grinding, thereby improving the grinding efficiency.

2. After the stubborn stones in the autogenous mill are crushed and magnetically separated, the medium ore returns to the autogenous mill for re-grinding, and the closed-circuit autogenous grinding process is changed to a semi-closed-circuit autogenous grinding process.

3. Change the closed-circuit autogenous grinding process to an open-circuit autogenous grinding process: After the stubborn stones in the autogenous mill are discharged, they are crushed and dry-type magnetically separated, and the medium ore enters the ball mill for re-grinding.

Through the above measures, the magnetite ore dressing plant can effectively improve production efficiency, reduce energy consumption, and improve economic benefits. The process flow design of the magnetite beneficiation plant covers many aspects of technical optimization, aiming to improve the beneficiation efficiency and economic benefits. By using a pre-selection process to remove surrounding rock during the crushing and screening stages, the concentrator effectively improves the ore grade and reduces grinding energy consumption. At the same time, the strategy of “more crushing and less grinding” is implemented to transfer energy consumption to the crushing stage, further reducing overall energy consumption. Based on the characteristics of raw ore, the combined process of stage grinding and stage separation optimizes the treatment effect, significantly reducing the amount of tailings and improving the quality of the concentrate.

In addition, the updating of magnetic separation equipment and the application of fine screening and regrinding technology have continuously improved the separation accuracy and efficiency. The introduction of semi-autogenous grinding technology has improved grinding efficiency, reduced energy consumption, and enhanced production capacity and economic benefits. These optimization measures comprehensively improve the overall performance of magnetite beneficiation, making ore dressing more efficient and economical.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE

.jpg)