Tin mining and processing have been around for thousands of years in human

civilization. From Bronze Age tools to modern electronic products, tin can be

found everywhere. Today, we also use tin in modern industries such as solder,

lithium batteries, and photovoltaic modules. This article introduces the methods

and equipment for tin mining and processing, and lists a case study of tin

mining in Indonesia.

The main tin mining areas are China, Indonesia, Congo, Peru and other

countries. The types of deposits are: primary rock tin ore and secondary placer

tin ore. Rock tin ore includes vein deposits in Cornwall, England, and skarn

deposits in Gejiu, China. Placer tin ore is mostly a riverbed or seaside ore

deposit, such as Bangka-Belitung in Indonesia.

Use the table of contents below to navigate through the guide:

01Tin Mining Methods & Equipment

1. Rock tin mining methods & equipment

Underground mining system: Cut-and-Fill Stoping is suitable for regular ore

bodies with a vein thickness of 1-5m and an inclination angle of >45°, with a

recovery rate of up to 85% and a surface settlement of <5cm. Key equipment:

tunneling trolley, scraper, support system, etc.

Open-pit mining system: Step mining, requiring a step height of 10-15m (hard

rock)/5-8m (weathered layer), a slope angle of 55-65°, and a safe platform width

of ≥4m. Key equipment: hydraulic shovel, drilling rig.

2. Sand tin mining methods & equipment

Dredging system. Applicable to ore bodies with a ore layer thickness of

≥1.5m, a tin content of >0.02%, and a groundwater depth of <10m. Key

equipment: bucket wheel dredger, suction dredger.

02Tin Processing Methods & Equipment

The mined tin ore needs to be further processed to extract tin from the tin

ore. First, the mined tin ore is crushed and ground to a fineness of P80≤75

microns. Then gravity separation and flotation are used to extract tin.

1. Gravity separation

The working principle of gravity separation is to separate tin from gangue

minerals by using the density difference between tin and gangue minerals. In the

roughing stage, a spiral chute is used to improve the grade of tin, and then in

the concentrating stage, a shaking table is used to further improve the tin

grade and recovery rate. Key equipment: jig, spiral chute, shaking table.

2. Flotation

Flotation is the use of flotation reagents to change the physical and

chemical properties of the surface of tin ore, thereby separating tin from

gangue minerals. Styrene phosphonic acid is used as a cassiterite collector,

water glass is used as a silicate inhibitor, and copper sulfate is used as an

activator to jointly complete the tin extraction. Lime is then used to adjust

the pH value of the slurry to 6.5-7.5. The flotation operation is completed

through three processes of roughing-sweeping-concentrating. Key equipment: KYF

flotation cell, XCF flotation cell.

After the tin ore is beneficiated, the tin concentrate is smelted and refined

to obtain tin ingots, tin particles and other products, as well as a variety of

by-products.

03Indonesia Tin Mining Case

1. Ore deposit type: coastal alluvial sand ore, with a 3-8m

thick ore layer and a 0.5-2m overburden thickness. Cassiterite occurrence: -2mm

particles account for 85%, coexisting with ilmenite and zircon.

2. Mining process: Backhoe excavator strips the overburden,

24-inch bucket wheel dredger mines the sand tin ore, and tailings backfill is

completed by hydrocyclone cyclone classification and then transported by

pipeline.

3. Processing technology: spiral chute completes roughing,

coarse concentrate grade is 25-30%, shaking table completes fine selection,

concentrate recovery rate is 92% (-0.074mm particle size), and finally

centrifuge is used to recover fine cassiterite.

4. Ore dressing indicators: tin concentrate grade is 62.5%,

recovery rate is 85.2%, middling grade is 8.7%, recovery rate is 9.1%, tailings

grade is 0.03%, recovery rate is 5.7%.

04Tin mining companies

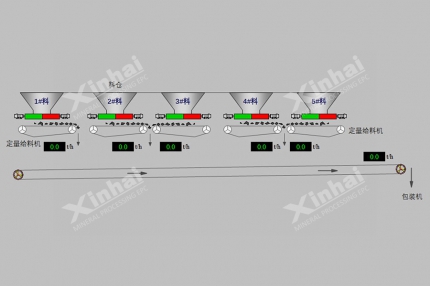

Xinhai Mining is a leading global provider of mineral processing solutions

(EPC+M+O services). As a tin mining company, Xinhai Mining has 28 years of

technical experience in tin mining and processing, and has served tin mining

projects in many countries. Xinhai combines intelligent control systems to

create intelligent, efficient, green and environmentally friendly tin mining and

selection production lines for customers.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE