Gold ore processing is a complex process that requires the selection of appropriate dressing methods and equipment based on the properties and composition of the ore. This article will introduce several common gold ore dressing methods in detail, including gravity separation, flotation and chemical separation, and explore their respective characteristics and scope of application.

Use the table of contents below to navigate through the guide:

01Gravity separation method for gold ore processing

Gold ore gravity separation method mainly uses the difference in density of gold and other associated gangue minerals for separation. Through the action of the medium fluid, ores of different densities are loosely layered in the gravity separation equipment to achieve mineral separation. Gravity separation process is often used as an auxiliary process for gold ore processing, suitable for recovering coarse gold, and is usually set as a pre-selection operation before flotation and cyanidation processes. The following are several common gravity separation equipment:

Jig: Jig is mainly used to process coarse minerals, especially for placer gold. This type of equipment works best under conditions where the specific gravity difference between minerals is large and the ore particles are dissociated. Jig is simple to operate and has a large processing capacity. It is an efficient gravity separation equipment.

Shaking table: Shaking table is mainly used to process fine-grained minerals, and separation is achieved through the shaking of ore particles and the flow of fluid medium. Shaking table is suitable for the separation of minerals with small ore particles and obvious density differences.

Spiral chute: Spiral chute is suitable for processing fine-grained gold ores with low mud content, and is mainly used to sort ore particles with a particle size of 0.03-0.6 mm. The spiral chute has low production cost and is easy to operate, making it an ideal equipment for processing fine-grained gold ore.

02Flotation process of gold ore processing

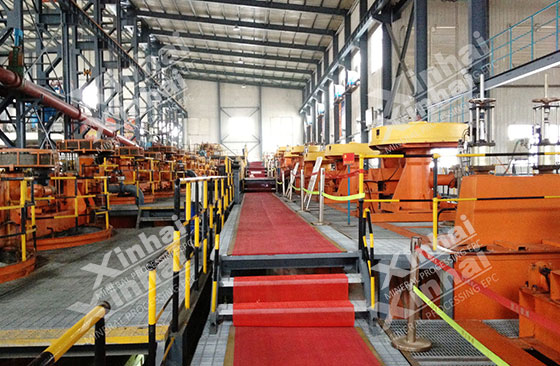

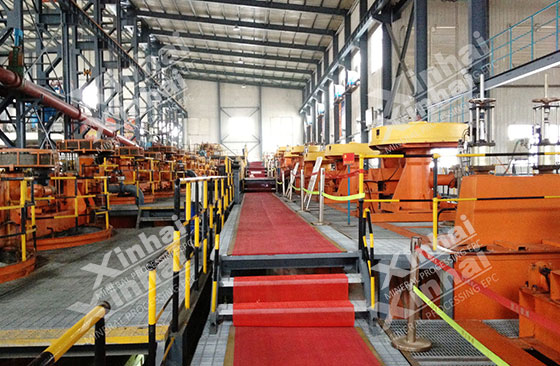

Flotation is one of the most commonly used methods in gold beneficiation, especially for rock gold beneficiation. The gold concentrate separated by flotation can be directly sent to the smelter for smelting. The main equipment required for flotation is the suction stirring flotation machine and the aeration stirring flotation machine:

Suction stirring flotation machine: This equipment mixes the minerals and reagents thoroughly by stirring and suction, generates bubbles, and floats the minerals attached to the bubbles. Common suction stirring flotation machines include SF type and BF type.

Aeration stirring flotation machine: The aeration stirring flotation machine inflates the flotation tank through an external air source to improve the flotation efficiency. Common models are KYF type and XCF type. This type of equipment is suitable for medium and large-scale beneficiation plants.

03Chemical beneficiation of gold ore processing

Chemical beneficiation is to extract gold from ore through chemical reaction. There are mainly two methods: amalgamation and cyanidation:

Amalgamation: Amalgamation is an ancient gold ore selection method, suitable for the selection of coarse-grained monomer gold. However, due to the large pollution it produces, it is less used today.

Cyanidation: Cyanidation is the most widely used chemical method in gold ore selection, which can be divided into two types: stirring cyanidation and percolation cyanidation. Cyanidation can process lower-grade gold ore and has a high recovery rate. In actual production, commonly used equipment includes zinc powder replacement device, leaching stirring tank, carbon screen, air lift, etc.

The selection of gold ore processing method needs to be comprehensively considered according to the properties of the ore and production requirements. Gravity separation is suitable for the recovery of coarse-grained gold, flotation method is often used for the extraction of rock gold, and cyanidation method is a common method for processing low-grade gold ore. By rationally selecting and matching these methods, efficient utilization of gold resources can be achieved.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE