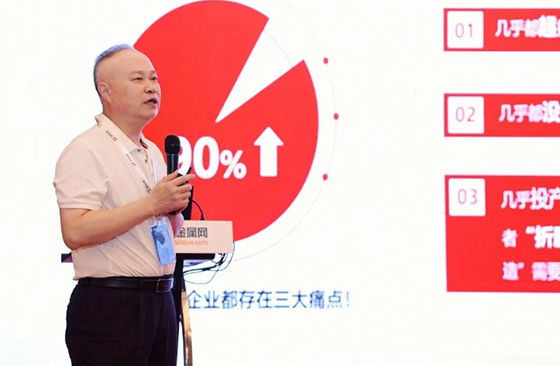

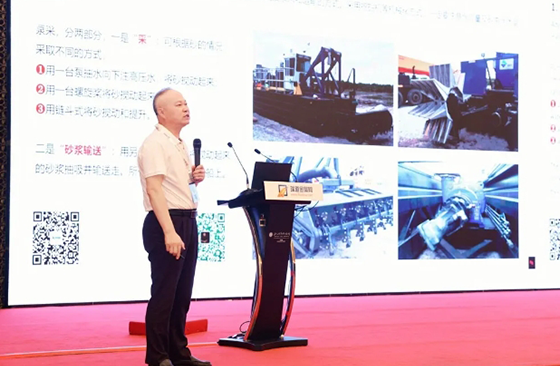

On April 17th-18th, the Global Zircon Conference 2024 was held in Haikou, Hainan. Xinhai Mining attended the conference with EPC+M+O Service. Chairman Mr. Elon Zhang was invited to attend and delivered a speech entitled "Experience Sharing of Zirconium-Titanium Ore Finishing and Low-Grade Ilmenite Ore Processing Technology". At this conference, Xinhai Mining sent experienced professional and technical personnel to understand the actual needs of customers face-to-face, answer zirconium ore beneficiation issues on-site, and help the development of the zirconium market!

(Elon Zhang was delivering a speech)

(Xinhai Mining Equipment Booth)

Use the table of contents below to navigate through the guide:

01Zirconium-titanium ore development status

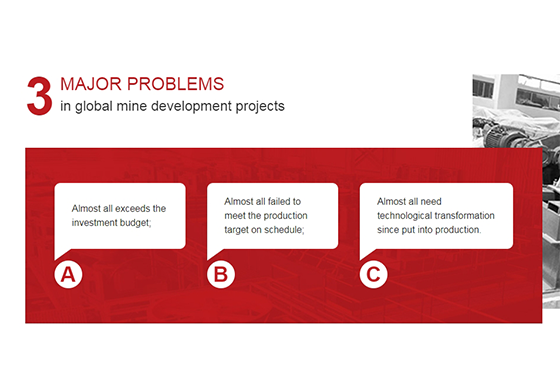

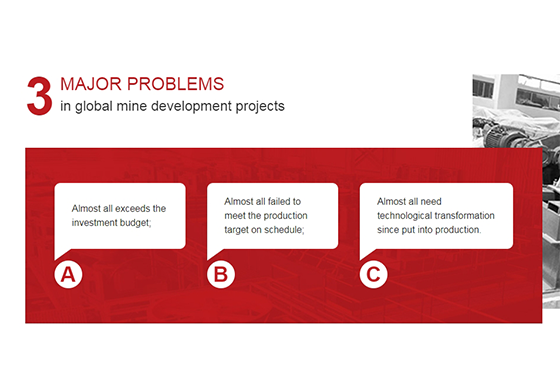

Zhang mentioned in his speech sharing experience in zirconium-titanium ore beneficiation technology that there are three major problems in the construction stage of seaside zirconium-titanium mines at home and abroad:

Almost all of them exceed the investment budget.

Almost none of them are put into production on schedule or meet production standards.

Almost all need technological transformation since put into production.

02Xinhai Mining seaside zirconium titanium ore finishing technology

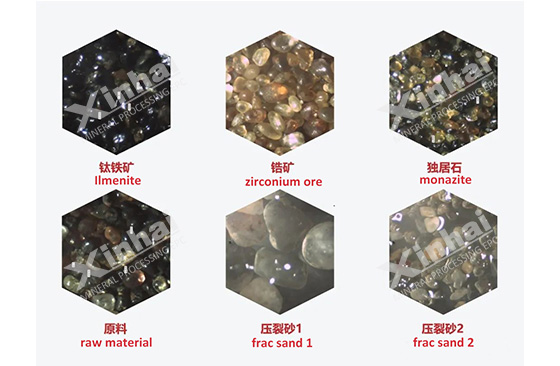

In recent years, Xinhai Mining has accumulated rich technical experience in the finishing of imported seaside zirconium and titanium ore, and has become an excellent service provider for zirconium and titanium ore comprehensive processing projects at home and abroad. In the design of the 1 million TPA zirconium-titanium ore project in Shandong, Xinhai Mining made a breakthrough in combining process innovation and design innovation, and updated and upgraded the design in terms of production scale, product solutions, continuous production, automation, green intelligence, etc.

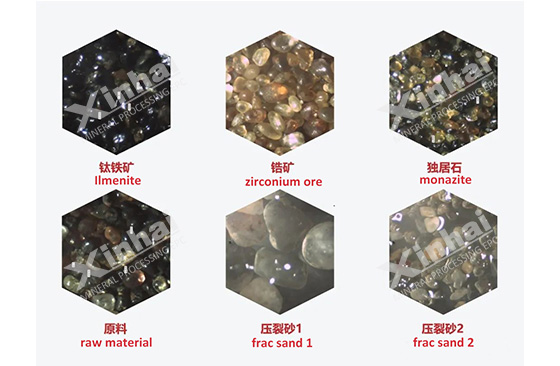

(Comprehensive mineral recovery)

1. Valuable minerals 100% comprehensive recycling

Accurate recovery of useful minerals without tailings emissions! On the basis that traditional projects can only recover ilmenite and zircon, the Shandong Zircon-Titanium Ore Processing Project has optimized the process and utilized the differences in magnetism, specific gravity, particle size, and conductivity between minerals to accurately recover 15 kinds of useful minerals. Achieve the goal of refined and comprehensive recovery of all valuable minerals.

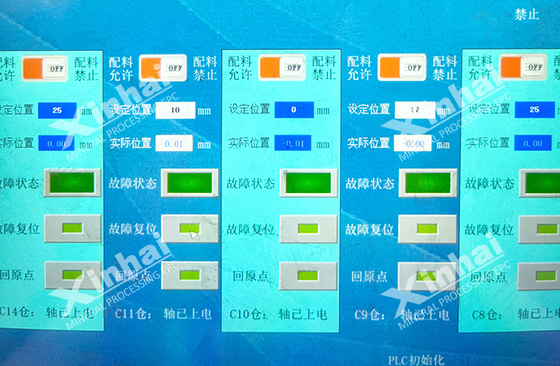

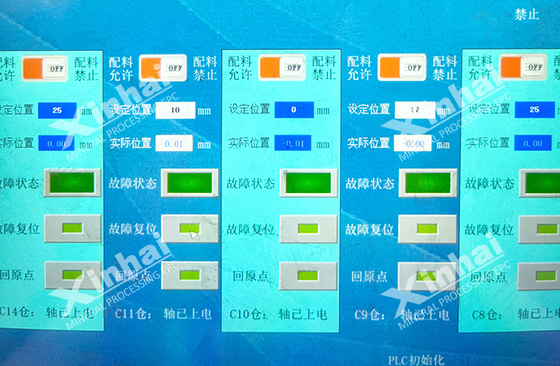

2. Automation and intelligence

Xinhai Mining planned and designed workshop-level and factory-level centralized control rooms for the Shandong zirconium-titanium ore project to improve the production automation and intelligence level of the mineral processing plant.

(Automatic batching monitoring system)

3. Intensive environmental protection design

The zirconium-titanium ore dressing plant designed and constructed by Xinhai Mining adopts intensive design. The modern new steel structure factory building is fast to construct, takes up less space, saves investment and has beautiful appearance. Water treatment, material transportation, dust noise, etc. all adopt high-standard environmentally friendly designs, which are green and low-carbon.

(Intensive factory area)

03Xinhai Mining innovative process for low-grade ilmenite processing

(Rendering of low-grade ilmenite dressing plant)

1. New crushing process - "crushing + high pressure roller mill + ball mill"

The conventional crusher is replaced by a high-pressure roller mill with a large processing capacity and high equipment operation rate, and the ore is ground to 1-0 mm by high-pressure roller, which truly realizes more crushing and less grinding in the mineral processing plant.

2. Ultra-fine powdered ore dry separation process

Using the ultra-fine particle dry ore dry separation process, the -1mm dry separation tailings throwing rate reaches 50%, which not only reduces the amount of ore entering the grinding mill, but also reduces the power consumption of the mill. And it also reduces the pressure on the tailings reservoir and reduces the tailings. The warehouse covers an area and the mine is green and environmentally friendly.

3. Titanium “Strong Magnetic + Flotation” Process

This process can enrich low-grade titanium to a flotation level before flotation, and then select it through a high-concentration titanium flotation process. The conventional flotation concentration is 30-40%, and the high-concentration flotation concentration is 45%. The ultra-high-concentration flotation concentration used in this project is 50-60%. The titanium selection effect is good and the technology is reliable.

4. Vertical mill for regrinding titanium rough concentrate

Vertical mill is a vertically installed fine grinding equipment with a stirring device. This equipment can perform fine grinding efficiently and prevent over-grinding. And it is simple to install and occupies a small area. Moreover, it has small vibration and low noise during operation, which can improve the working environment.

(Xinhai Mining Vertical Agitation Mill)

At present, the reserves and output of zirconium resources in our country are relatively small, and the country is highly dependent on foreign countries. The development and utilization of domestic zirconium ore resources faces certain challenges. China's zirconium ore industry urgently needs to find new application spaces and increase the added value of products. As the proposer and practitioner of EPC+M+O Service, Xinhai Mining will provide customers with intelligent, efficient and high-quality zirconium-titanium ore project construction solutions through technological innovation, industrial upgrading and other measures to improve resource utilization efficiency, reduce external dependence, and achieve sustainable development of the zirconium ore industry!

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE