The total construction period was 198 days!

The Henan 1500TPD silver-lead-zinc-gold polymetallic ore flotation expansion

project, undertaken by Xinhai Mining, officially started in early April 2024 and

was completed and put into production by early November 2024.

Leveraging its "full industrial chain service for mining (EPC+M+O)" model,

Xinhai Mining independently handled the entire process — from process design,

equipment manufacturing, civil construction, to installation, commissioning,

construction management, and quality control.

The project was completed on schedule, put into production on time, and

achieved production targets ahead of schedule, fully demonstrating Xinhai

Mining's strong capabilities in large-scale mining engineering!

Use the table of contents below to navigate through the guide:

01Project Background

Xinhai Mining's 1500TPD silver-lead-zinc-gold polymetallic ore project is

located in Henan Province.

The project's client is a Canadian listed company with strict requirements

for quality standards, construction period, and cost control.

The original concentrator already had two 900TPD production lines. Due to the

company’s strategic development needs, the client decided to expand by adding a

1500TPD production line adjacent to the original concentrator.

This expansion project not only tests Xinhai Mining’s design expertise and

engineering experience, but also requires efficient coordination of resources

throughout the construction process to ensure on-time, high-quality delivery

without affecting the normal production of the original concentrator.

It serves as a comprehensive test of Xinhai Mining’s engineering and

construction capabilities.

Project Overview

Ore properties

Silver, lead, zinc and gold polymetallic mine, mainly lead and zinc.

Process

Crushing and Screening Process:

A three-stage, one closed-circuit crushing process is adopted. The feed size

is -200 mm, and the screened product size is -15 mm. The production capacity is

approximately 200 t/h.

Grinding Process:

A one-stage closed-circuit grinding and classification process is used, with

a grinding fineness of -200 mesh accounting for 60%–65%.

Gravity Separation Process:

The grinding circuit is equipped with a Nelson gravity separation system. The

qualified slurry under the screen is transported to the Nelson concentrator and

shaking table for gravity separation of gold ore, with Nelson concentrate being

preferentially recovered.

Flotation Process:

Lead-zinc ore flotation adopts the process of preferential lead flotation,

followed by zinc flotation from lead tailings.

Lead flotation: One roughing, three scavenging, and three cleaning

stages.

Zinc flotation: One roughing, four scavenging, and three cleaning stages.

Dewatering Process:

Lead and zinc concentrates are dehydrated separately. A two-stage dewatering

process is used: the first stage employs a thickener, and the second stage uses

a ceramic filter.

02Xinhai Solution

Engineering

Xinhai Mining Design Institute designed the process flow, equipment

selection, and configuration plan for the expansion of the beneficiation plant

based on the on-site production process. The project was designed to expand to

1,500 TPD, with an actual reserved production capacity of 1,800 TPD.

Xinhai Mining's design team became involved at the early stage of the

project, conducted a field investigation at the project site, and gained an

in-depth understanding of the local material supply conditions. By optimizing

the design and reasonably selecting equipment and materials, the project cost

was effectively controlled, ensuring the operability and cost-effectiveness of

the design plan.

Procurement

Xinhai Mining has strong equipment manufacturing capabilities and can produce

more than 1,000 types of equipment for mining, beneficiation, and smelting. It

can provide a full set of main and auxiliary equipment for mines with a

production capacity of up to 50,000 tons/day.

For the Henan polymetallic mine project, Xinhai Mining supplied thickeners, agitation tanks, and other beneficiation equipment. In terms of material

procurement and usage, Xinhai strictly controls material specifications and

models, and minimizes the variety of materials such as concrete, steel bars, and

bolts, thereby simplifying the procurement process.

Due to the extremely limited storage space at the project construction site,

on-site material procurement followed a "small-quantity, multiple-batch"

strategy, with timely planning, approvals, and purchasing. Materials shipped

from the company also arrived at the site on schedule and in an orderly manner,

ensuring that the project construction progress was not delayed.

Construction

As the general civil engineering contractor for the Henan

silver-lead-zinc-gold polymetallic mine project, Xinhai Mining independently

undertook all engineering work within the scope of the plant construction. This

included equipment procurement and supply, civil engineering and installation,

commissioning tests and inspections, system trial operations, defect

elimination, performance testing, system performance acceptance, technical and

after-sales services, and project completion acceptance.

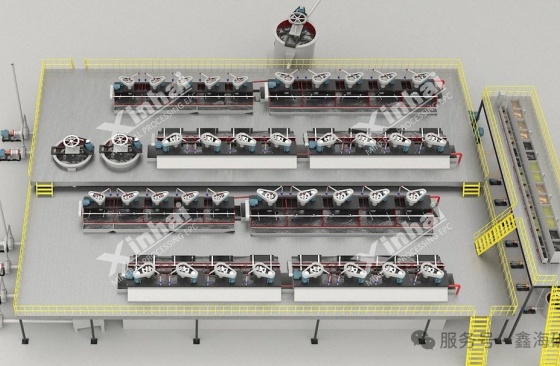

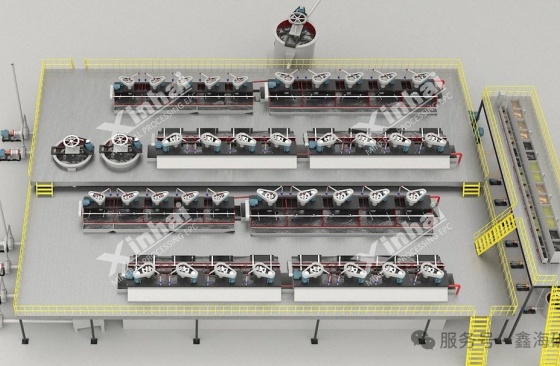

The scope covered mineral processing equipment, electrical engineering,

process pipelines, process platforms and other non-standard parts, steel

structure plant construction, powder ore bins, grinding and flotation workshops,

concentrate thickening, concentrate filtration, circulating water and return

water systems, substations, communication systems, instrument control systems,

retaining walls, and supporting auxiliary facilities.

03Project Highlights

EPC General Contracting – Full Industrial Chain Service

Xinhai Mining provides "mining full industrial chain services (EPC+M+O)" for

the Henan polymetallic mine project, covering the entire process from process

design and engineering construction design to equipment manufacturing, civil

construction, and installation of the beneficiation plant, as well as

construction management and quality control. This one-stop solution reduces

project management difficulties, ensures the efficient and high-quality

advancement of the project, and fully demonstrates Xinhai Mining's professional

capabilities and customized service advantages in the field of mining services.

At the same time, by carrying out design and construction simultaneously under

the EPC model, the construction period is shortened, creating significant value

for the project.

Innovative thinking - mine design optimization

Xinhai Mining Design Institute has enhanced ore processing capacity,

production flexibility, and metal recovery rates through design optimizations

such as adding powder ore bins, an intelligent waste disposal system, and a

third series of grinding plants. These improvements have helped the project

achieve higher production efficiency and better resource utilization. The key

design highlights include:

Added Powder Ore Bin and Intelligent Waste Disposal System

Expanded the Third Series of Grinding Plants

Added the Third Series of Flotation System

Upgrade of Concentrate Concentration System

Efficient mine management

Xinhai Mining has established a scientific and standardized mine management

system, along with comprehensive rules and regulations, to ensure the effective,

safe, and reliable operation of the project. In terms of project quality

control, it strictly uses brand-name building materials and follows standardized

construction practices to ensure quality. It also implements safety inspection

mechanisms and conducts regular training to reinforce safety. Regarding

personnel training, the company has developed a standardized process system that

includes material procurement, organizational structure, and code of conduct.

The project implements an assessment and reward system, holds regular weekly

meetings to ensure the system's enforcement, and sets a benchmark for mine

project management through refined management and innovative mechanisms.

conclusion

The successful commissioning of the Henan 1500TPD silver-lead-zinc-gold

polymetallic mine project not only highlights Xinhai Mining's strength in

large-scale mining engineering construction but also showcases the advantages of

its "full industrial chain mining service (EPC+M+O)" model. With its professional

technical expertise and efficient construction management, Xinhai Mining ensured

the project was completed and put into production within 198 days, delivering a

satisfactory result to the client. Moving forward, Xinhai Mining will continue

to leverage its top-tier qualifications for general contracting in mining

engineering and its extensive industry experience, while upholding the service

concept of "what you need is what we do." The company aims to provide more

efficient and reliable "full industrial chain mining services (EPC+M+O)" to

global mining clients, helping drive the green and intelligent transformation of

the global mining industry.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE