Nickel oxide ore is an inorganic compound composed of nickel and oxygen, with the chemical formula NiO. Nickel oxide is insoluble in water and liquid ammonia, but soluble in sulfuric acid, nitric acid, hydrochloric acid and ammonia water. It has a cubic crystal structure, similar to sodium chloride, in which each nickel atom is surrounded by six oxygen atoms in close proximity, forming a regular octahedron with the nickel atom at the center. Due to the complex nature of nickel oxide ores, flotation is the main method for mineral processing. Currently, common flotation process methods include direct flotation, sulfide flotation and combined flotation.

Use the table of contents below to navigate through the guide:

01Direct flotation process of nickel oxide ore

Direct flotation process is a method of separation of nickel oxide ore from gangue minerals by using fatty acid collectors in a suitable pulp environment (usually an adjuster is required to adjust the pH value, etc.) to make the surface of nickel oxide ore hydrophobic, and bring it to the pulp surface with the help of bubbles to form a foam layer. Collectors are mostly fatty acids, such as oleic acid, sodium oleate, etc., and adjusters are mostly alkaline, such as sodium carbonate, sodium hydroxide, etc. The process is usually: roughing, concentrating and scavenging, among which roughing is to select most of the useful minerals into the rough concentrate; concentrating is to further purify the rough concentrate and remove impurities; scavenging is to re-select the flotation tailings to recover the remaining useful minerals and improve the recovery rate.

02Sulfide flotation process of nickel oxide ore

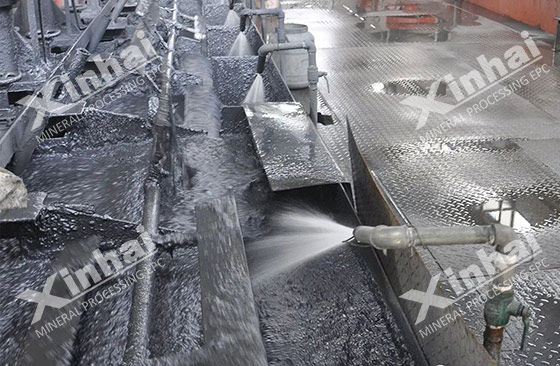

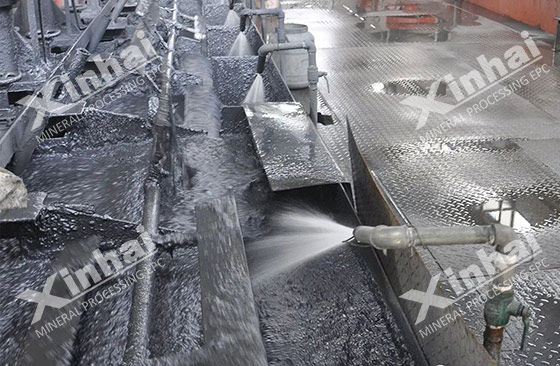

Nickel oxide ore sulfide flotation process is a beneficiation method that adds sulfiding agents to sulfide the surface of nickel oxide ore to increase its floatability, and then uses the principle of froth flotation to separate nickel minerals from gangue. The flotation process is to first add sulfiding agents, such as sodium sulfide, sodium hydrosulfide, etc., to the slurry to form a sulfide film on the surface of the nickel oxide ore. The surface properties of the sulfided minerals change and become easier to be captured by traditional flotation collectors. This method is similar to the direct flotation method, including roughing, cleaning and scavenging, but due to the addition of sulfidation treatment, it is necessary to control the amount of sulfiding agent and sulfidation time to ensure the sulfidation effect. This method is mostly suitable for processing some complex nickel oxide ores, especially ores with very fine particle sizes where nickel is dispersed in gangue minerals in an isomorphous manner.

03Nickel oxide combined flotation process

Nickel oxide ore often coexists with other valuable elements, such as copper and cobalt. For this type of copper oxide, single flotation process may not necessarily achieve an ideal recovery rate. Therefore, a combined flotation process is often used to achieve ore dressing. Multiple flotation methods such as direct flotation and sulfide flotation can be combined. According to the properties and characteristics of the ore, different flotation methods are selected and applied at different stages to achieve ideal flotation effects.

The above are several flotation methods for nickel oxide ore. In actual ore dressing plants, the flotation of nickel oxide will select different flotation methods according to the properties of nickel ore. Therefore, it is recommended to conduct ore dressing tests and design suitable nickel oxide flotation process through analysis.

Xinhai Mining has many years of experience in nickel ore dressing. It can conduct ore dressing tests, design nickel ore dressing processes, and provide complete sets of nickel ore dressing equipment. At the same time, it can also install and debug ore dressing equipment. If there is any need for later operation and management operations, please feel free to consult.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE