With the exploitation and utilization of rich iron ore resources, the proportion of poor ores and difficult-to-separate ores has gradually increased. Siderite often exists in the form of paragenetic ore, often associated with hematite and magnetite. Due to the low iron content in siderite, its beneficiation difficulty increases, and the influence of associated minerals makes its beneficiation process even more difficult. Therefore, it is difficult to obtain ideal separation effects by using single iron ore beneficiation processes such as gravity separation, magnetic separation, and flotation, and the grade and recovery rate of the concentrate are not high. With the continuous development of technology, a variety of new iron ore beneficiation processes have been applied to the treatment of siderite-hematite iron ore. The following will discuss the mineralogical characteristics of siderite-hematite, the combined process of magnetic roasting-weak magnetic separation-reverse flotation, the combined process of strong magnetic-gravity separation-flotation and the single flotation process, and explore their process characteristics and applicability.

Use the table of contents below to navigate through the guide:

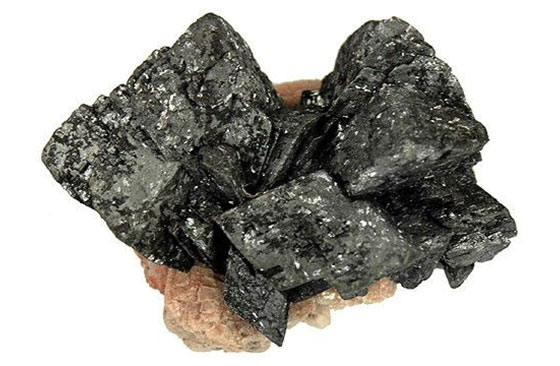

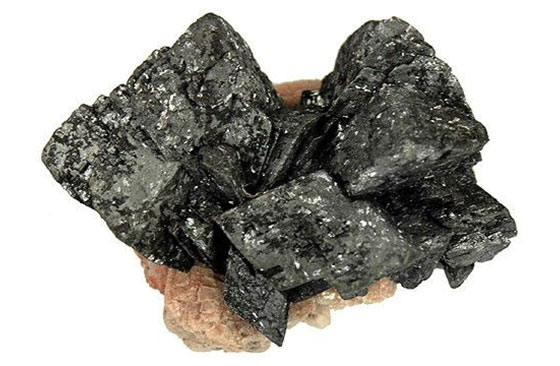

01Mineralogical characteristics of siderite-hematite

Siderite is a carbonate mineral with a relatively low iron content and is difficult to beneficiate. It is difficult to separate using traditional beneficiation methods, so special methods are required for treatment. Hematite is a weakly magnetic mineral and often coexists closely with siderite in composite ores, which increases the difficulty of beneficiation. Siderite-hematite composite ores also contain gangue minerals such as quartz, dolomite, and calcite, which also affect the beneficiation efficiency of iron ore.

In addition, siderite is prone to oxidation during the iron ore beneficiation process and turns into iron minerals that are difficult to separate. Therefore, when designing the beneficiation process of siderite, it is necessary to fully consider the thermal stability and physical and chemical properties of the mineral to improve the iron ore beneficiation efficiency.

02Siderite-hematite iron ore beneficiation process

1. Combined process of magnetic roasting-weak magnetic separation-reverse flotation

The selectivity of siderite can be improved by magnetic roasting. After the composite ore is crushed and ground to reach an appropriate particle size, it is subjected to magnetic roasting under certain temperature conditions. The siderite is reduced to magnetic iron minerals, and then weak magnetic separation is used to recover the magnetic iron ore. After that, the magnetic tailings are subjected to reverse flotation to remove gangue minerals such as siliceous and carbonates.

The magnetic roasting technology in this combined process effectively improves the magnetism of siderite, allowing it to be enriched by magnetic separation. The reverse flotation process can also further improve the grade of iron ore concentrate. This combined iron ore beneficiation method is mainly suitable for siderite-hematite composite ores with low iron ore grade and high silicon content.

2. Strong magnetic-gravity separation-flotation combined process

This process combines strong magnetic separation, gravity separation and flotation, and is suitable for the separation of minerals of different particle sizes. After pretreatment, the siderite-hematite composite ore is firstly recovered by strong magnetic separation process. Hematite and siderite lamp weak magnetic minerals are recovered by gravity separation method to reduce the subsequent burden. The flotation process is mainly to sort the unrecovered siderite, with the purpose of improving the recovery rate of siderite. This method is suitable for siderite-hematite iron ore containing a certain amount of magnetite and hematite.

3. Single flotation process

The flotation process is mainly used to recover siderite, but the floatability of siderite is poor, and the flotation conditions need to be optimized. During flotation, fatty acid and hydroxamic acid collectors are added to effectively separate siderite from gangue minerals. In addition, appropriate adjusters are used to improve selectivity and obtain high-grade siderite concentrate.

The above is a brief introduction to the mineralogical characteristics of siderite-hematite composite iron ore and different iron ore beneficiation processes. Different beneficiation methods are suitable for different types of iron ores. When designing beneficiation processes, beneficiation tests are used to determine the beneficiation characteristics of the ore and determine the best beneficiation conditions. Xinhai Mining can provide you with customized iron ore beneficiation processes and equipment, comprehensive beneficiation engineering services, and is committed to creating the greatest value for customers and promoting the sustainable development of the mining industry.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE