Flotation process is one of the commonly used methods in the ore separation process. It mainly uses the floatability of mineral surfaces for separation. In the flotation process, the addition of chemicals is crucial. The type and dosage of chemicals added have an important impact on the flotation effect. Understanding the flotation process and types of flotation reagents is one of the main ways to optimize and improve the existing flotation process. The following will introduce you to the flotation process and types of flotation reagents.

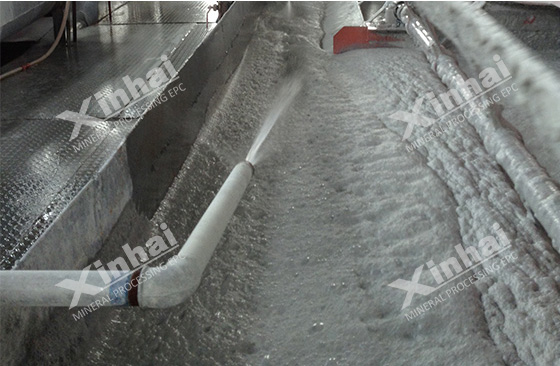

(Flotation equipment)

Use the table of contents below to navigate through the guide:

01Ore flotation process flow

The flotation method is mainly a method of sorting ground minerals based on different physical and chemical properties of the mineral surface. Generally divided into four stages.

(1) Ore grinding: Before flotation, the ore is crushed and ground to a certain particle size. The useful minerals and gangue minerals achieve monomer dissociation, making them suitable for flotation requirements.

(2) Slurry preparation: When preparing the slurry, adjust the slurry concentration and add flotation reagents to adjust the slurry pH. After adding flotation reagents, the surface properties of the minerals change, making them meet the selection requirements.

(3) Air introduction: Air is introduced into the flotation machine to form a large number of bubbles. The mineral particles adhere to the bubbles and float to the surface of the slurry together with the bubbles to form a foam layer.

(4) Foam collection: Use the scraper on the flotation machine to scrape out the floating foam products to achieve the purpose of flotation.

02Ragents used in ore flotation process

During the flotation process, various flotation chemicals need to be added to change the flotation properties of the mineral surface, such as the flotability of the mineral particles, the degree of air dispersion in the slurry, foam stability, etc., to ensure the smooth progress of the flotation process. According to different functional properties, flotation agents can be divided into three categories: collectors, frothers and adjusters. Adjusters can be divided into activators, inhibitors and pH adjusters.

(Collector)

1.Collector

The collector can interact with the surface of minerals to form a hydrophobic film on the surface of useful minerals, which facilitates the attachment of mineral particles and bubbles and separates the target minerals from gangue minerals. The collector can also increase the difference in wettability between minerals, improve the floatability of minerals that are not easily wetted, and adsorb on the bubbles to float to the surface of the slurry. The main types of collectors include sulfur compounds, hydrocarbon acids, amines and oils. Sulfide compound collectors are often used for flotation of natural metals, non-ferrous metal sulfide ores and sulfide oxidized ores. The types include xanthate, black powder, mercaptan, etc. Hydrocarbyl acid collectors are often used for flotation of oxidized ores, alkaline earth metal ores, silicate minerals, etc. The main types include oleic acid, oxidized paraffin soap, etc. Amine collectors are mainly used for flotation of quartz and aluminosilicate ores. Oil collectors are often used to flotate naturally hydrophobic minerals such as molybdenite, graphite, and natural sulfur. They can also be used as auxiliary collectors to flotate natural gold. The main types include kerosene, transformer oil, solar oil, etc.

(Foaming effect)

2. Frother

The purpose of adding a frother to the flotation slurry is to make the bubbles form a large amount of stable foam, which can be used as a floating medium for sorting buoyant and non-buoyant minerals. The principle of action is that the foaming agent can reduce the surface tension of the air interface in the water area, causing the inhaled air to rise through the slurry in the form of bubbles and accumulate on the surface of the slurry. Commonly used foaming agents in mineral processing plants mainly include No. 2 oil, camphor oil, heavy pyridine, cresyl acid, etc., among which No. 2 oil is the most widely used.

3.Adjuster

The main function of the regulator in the flotation process is to change the surface properties of minerals, improve the selectivity in the flotation process, enhance the efficiency of the collector, and improve the flotation conditions of the slurry. According to different medicinal properties, it can be divided into active agents, inhibitors and pH adjusters.

(1) Inhibitor: It can form a hydrophilic film on the mineral surface to prevent the collector from interacting with the mineral surface, thereby reducing the flotability of the mineral. Commonly used inhibitor types include: lime, cyanide, sodium sulfide, water glass, starch, etc.

(2) Activator: Its main function is to form a film on the surface of the mineral to promote the attachment of the collector and improve the floating ability of the mineral. It also removes inhibitory films from mineral surfaces and restores the mineral's original planktonic activity. Commonly used activators include sodium sulfide, lead nitrate, copper sulfate, etc.

(3) pH adjuster: Commonly used alkaline pulp conditioners include lime, sodium carbonate, and caustic soda. The acid pulp conditioner is mainly sulfuric acid.

(Flotation process site)

The above is a brief explanation of the flotation process and types of flotation reagents. In actual production, the design of the flotation process, the selection of chemicals and the determination of additive dosage need to be based on the properties of the ore. The mineral processing test can provide a theoretical basis for the design of the flotation process and the determination of the chemical system. Appropriate flotation process and reagent addition system can improve flotation efficiency and effect, and further improve the recovery rate and economic benefits of concentrate.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE