Iron has good thermal conductivity, ductility, electrical conductivity and plasticity. It can also be alloyed with other metals to meet the needs of different industrial conditions. As the mining of iron ore resources continues to increase, the quantity of high-grade iron ore resources is getting smaller and smaller. In order to obtain more iron metal resources, metals need to be recovered from some poor ore resources or tailings. At present, magnetic flotation technology has become one of the commonly used technologies for recovering iron metal from lean ore resources. This technology has lower cost and higher efficiency. This technology is a new type of iron ore beneficiation technology with wide application prospects. The following will introduce you to the application of magnetic flotation technology in iron ore beneficiation to help you better understand this process.

Use the table of contents below to navigate through the guide:

01What is magnetic flotation technology?

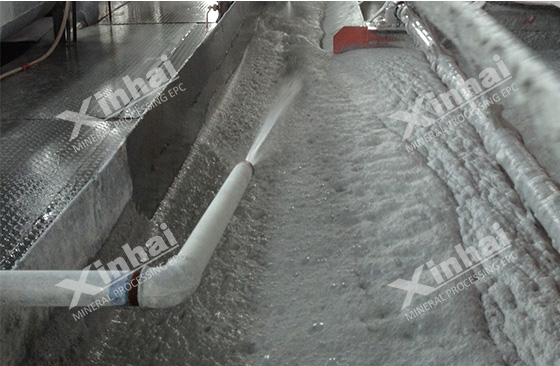

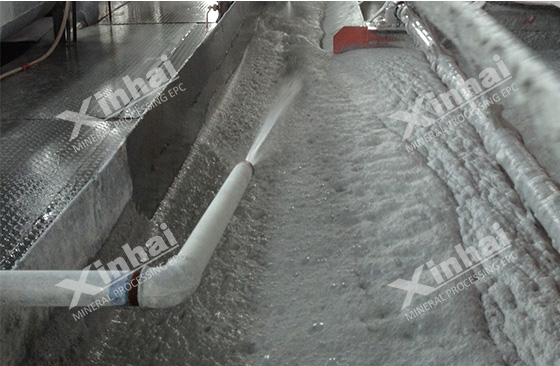

The principle of magnetic flotation technology is to use the differences in physical and chemical properties on the surface of mineral particles to separate the required mineral particles from a large amount of ore. The process is carried out in an environment where gaseous, liquid and solid substances are mixed, and different metal and non-metal elements are mixed. As the process proceeds, hydrophobic minerals will adhere to the bubbles, while soluble substances will remain in the aqueous solution. The magnetic flotation process will be affected by many factors. Therefore, when using this method for iron ore beneficiation, special attention should be paid to avoid an increase in the residual amount of impurities in the slurry, thereby affecting the separation efficiency. Because iron ore is magnetic and easier to separate and extract, the magnetic flotation process of iron ore is low-cost and simple.

02Factors affecting efficiency of magnetic flotation technology

1. Influence of feed concentration

There are three ways to express the feed concentration, solid mass, percentage concentration and liquid-to-solid ratio. In general flotation, the feed concentration needs to be adjusted according to the actual situation. When the floatability of lean ore is poor, a lower concentration needs to be selected, and conversely, the feed concentration needs to be increased. The feed concentration has a great impact on the cost of the entire production process. Although reducing the feed concentration can improve the beneficiation effect of the magnetic flotation process, it will also increase the amount of flotation reagents, thereby increasing production costs. In addition, reducing the feed concentration will also increase the workload of the flotation machine and generate more energy consumption.

2. Effect of temperature

During the flotation process, it is necessary to strictly control the temperature of the slurry, and try to increase the temperature of the flotation slurry to reduce the viscosity of the slurry and avoid adhesion problems. As the temperature increases, the gas and most impurities in the slurry will precipitate. In addition, appropriate temperature rise can reduce the viscosity of the non-polar oil collector, allowing it to be fully and evenly dispersed into the slurry for adsorption and collection work. Increasing the temperature can improve the working efficiency of collectors and bubble molecules, and improve the efficiency of flotation work. Temperature will affect the magnetism of iron and iron compounds to a certain extent, so the temperature should not be too high to prevent the magnetism from weakening and reducing the adsorption capacity, thereby affecting the efficiency of flotation work.

3. Influence of dosing method

The dosing methods during the flotation process can be divided into two types: one-time dosing and staged dosing. One-time dosing refers to putting all the reagents into the slurry pretreatment device in advance, while staged dosing means adding the flotation reagents to the device and the flotation chamber respectively. The difference between the two is that the one-time dosing method is easy to operate and can greatly increase the speed of the flotation process. However, this dosing method will cause the concentration of flotation reagents to be too high, reduce the selectivity of bubbles, and thus affect the mineral processing efficiency. When the flotation agent is not fully dispersed throughout the system, the amount of flotation agent in the subsequent process will also be reduced as the foam overflows. For less uniform lean ores, the one-time dosing method cannot be used. The step-by-step dosing method is cumbersome to operate and the calculations are complicated, so it can be applied to the flotation of minerals that are difficult to float. The segmented dosing method can also prevent flotation reagents from being excessively adsorbed and overflowed, and can reduce the dosage of flotation reagents, thereby reducing production costs. These two dosing methods have their own advantages and disadvantages, and they need to be chosen according to the actual situation.

The above content is a brief introduction to magnetic flotation technology and influencing factors. Improving the efficiency of iron ore resource development requires appropriate adjustments based on the original mineral processing technology to ensure that the selected iron ore can meet the smelting requirements. Xinhai Mining recommends conducting a beneficiation test of iron ore resources to determine the beneficiation plan and equipment, which can not only comprehensively utilize mineral resources, but also improve the economic benefits of the ore dressing plant.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE