Gravity separation for gold extraction is an ancient and effective beneficiation technology. It is a beneficiation method based on the density difference between gold and other minerals to separate gold from impurities such as gangue in a gravity field or centrifugal field. The density of gold is relatively high, usually around 19.3g/cm³, while the density of most gangue minerals is relatively small. This obvious difference provides a physical basis for gravity gold separation. Generally, gold ore particles with a density greater than that of heavy media will sink, while gangue minerals with a density less than that of heavy media will float up, thus achieving separation.Gravity separation has a long history of application in placer gold beneficiation, and is often used as an important pretreatment or selection link in the beneficiation process of rock gold ore.

Use the table of contents below to navigate through the guide:

01Gravity separation methods for gold extraction

Gravity separation methods for gold extraction can choose different gravity selection methods according to the different particle sizes of gold ore, including jigging, shaking table, spiral chute and heavy medium.

1. Jigging for gold extraction

Jigging is based on the movement difference of mineral particles in vertical alternating water flow. In the jig, the water flow rises and falls periodically. When the water flow rises, the bed is lifted and the mineral particles begin to loosen; when the water flow falls, the gold particles with higher density can move downward through the gaps in the bed faster, while the gangue minerals with lower density remain in the upper layer. Under the combined influence of gravity, water flow impact force and interaction between particles, the gold particles gradually concentrate at the bottom of the bed during multiple cycles to achieve sorting.

Jigging has good adaptability to gold ores of different particle size ranges. It can effectively select both coarse and fine ores, and can obtain gold concentrates with a certain grade. However, the effect of jigging gold selection is affected by the particle size composition of the ore and the operating parameters of the jig (such as stroke, number of strokes, etc.). It is suitable for beneficiation plants of various sizes. It can be used as a roughing equipment to process a large amount of raw ore, and it can also play a role in the beneficiation process.

2. Shaking table for gold extraction

Shaking table is to use the difference in the movement of ore particles on the inclined bed surface for sorting. The bed surface of the shaking table is usually covered with grooves or paved with rough paving materials. When the shaking table shakes, the slurry forms a fan-shaped flow on the bed surface. At the same time, due to the lateral water flow generated by the tilt and shaking of the bed surface, the gold particles move laterally along the bed surface under the combined effect of gravity, friction and water flow impact, and are enriched in different areas on the bed surface according to their density and particle size.

Shaking table has a good effect on the sorting of fine and micro-fine gold ores, and can obtain higher-grade concentrates. However, the processing capacity of the shaking table is relatively small, and it is suitable for small-scale beneficiation plants for beneficiation operations or processing low-grade ores.

3. Spiral chute for gold extraction

Chute selection is the use of the movement characteristics of mineral particles in a chute with a certain slope for sorting. The chute body is usually a plane with a certain degree of roughness or a bottom with specific patterns. When the slurry enters the chute, it flows down along the chute under the action of gravity. At the same time, due to the certain slope of the chute and the fluidity of the slurry itself, a certain water flow dynamics is generated. Under the combined effects of gravity, friction between the chute body and other particles, and the impact of water flow, gold particles gradually settle and move in the chute. According to the difference in density between gold particles and other minerals, gold particles tend to gather in a specific area at the bottom of the chute, while gangue minerals with lower density are carried away with the water flow.

Spiral chute has a more significant effect on the separation of medium and fine-grained gold ores, and can obtain relatively high-grade gold concentrate. However, the recovery rate of chute gold dressing may be affected by factors such as slurry flow rate and ore feeding volume. It is suitable for processing ores containing less coarse gold particles and is used in some small ore dressing plants or as a link in the joint beneficiation process. Widely used.

4. Heavy medium for gold extraction

Heavy medium ore dressing is to use the different floating and sinking characteristics of gold and other minerals in a medium with a density greater than water to separate them. Heavy medium is usually a suspension formed by mixing finely ground high-density solid particles with water, and its density can be adjusted as needed. When gold ore particles enter the heavy medium, under the combined effect of gravity and medium buoyancy, gold particles with a density greater than that of the heavy medium will sink, while gangue minerals with a density less than that of the heavy medium will float. In this process, since the heavy medium is evenly distributed in the ore dressing equipment, the gold particles, with their greater density, overcome the resistance of the medium and settle to the bottom of the equipment, while those minerals with lower density are pushed to different directions by the buoyancy of the medium.

Heavy medium is ideal for ores with relatively large particle sizes. It can efficiently separate gold from a large amount of gangue minerals to obtain gold-enriched materials with higher purity. However, this method requires precise control of the density of the heavy medium, and the recovery and purification process of the medium is relatively complicated. It is suitable for processing ores with moderate particle sizes and obvious differences in the density of gold and gangue minerals. It can play the advantages of efficient separation in large-scale mineral processing operations and improve the overall efficiency of mineral processing.

02What are the gravity separation equipment for gold extraction?

The equipment commonly used in gravity separation and gold extraction mainly includes jigs, shaking tables, spiral chutes and heavy medium cyclones.

1. Gravity separation jig

Jigs are an important mineral separation equipment that realizes separation based on the difference in the movement of mineral particles in vertical alternating water flow. This equipment can play an important role in the separation of placer gold, rock gold, and other metal ores, and its equipment structure is relatively stable and the separation effect is relatively stable. Depending on the model, there are several types of diaphragm jigs and screen side air chamber jigs.

2. Gravity concentration shaking table

The shaking table is a device that uses the difference in the movement of ore particles on the inclined bed surface for sorting. It has a good sorting effect on fine and micro-fine gold ores and can obtain high-grade concentrates, but its processing capacity is small and it is suitable for concentrating or small-scale ore dressing plants. There are flat shaking tables and multi-layer shaking tables.

3. Gravity separation chute

The spiral chute is a device that uses a spiral trough for mineral separation. After the slurry is fed from the upper end of the spiral chute, under the combined effects of gravity, centrifugal force, friction and water flow impact, the gold particles tend to move along the bottom of the trough due to their high density, while the gangue minerals tend to move on the upper part of the trough, thereby achieving separation. It has a simple structure, is easy to operate and has a good effect on the separation of fine-grained gold.

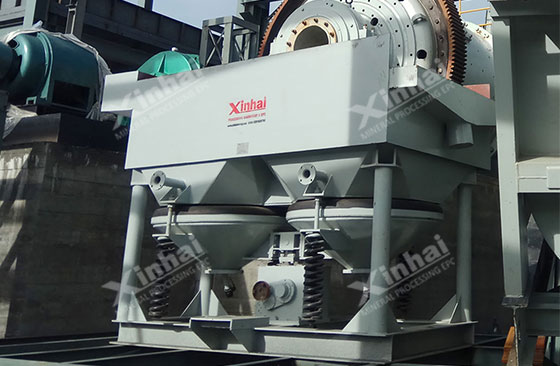

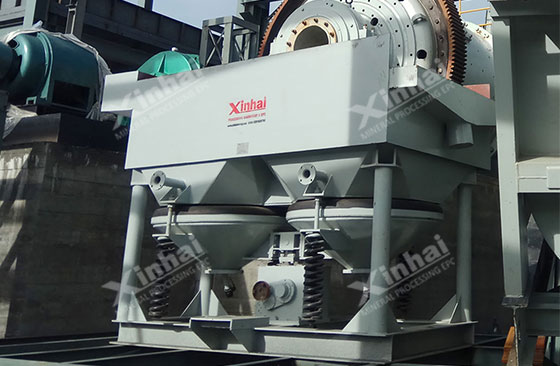

4. Heavy medium separator

A heavy medium separator is a device that separates mineral particles based on their different floating and sinking characteristics in a medium with a density greater than that of water. This type of heavy separation equipment is ideal for separating ores with relatively large particle sizes, and can efficiently separate gold from a large number of gangue minerals. However, it requires precise control of the medium density, and the recovery and purification process of the medium is relatively complicated. It is suitable for processing ores with moderate particle sizes and obvious differences in the density of gold and gangue minerals.

The above is an introduction to gravity separation methods and equipment for gold extraction. In actual ore dressing plants, the gold ore gravity separation process needs to be determined according to the properties of the gold ore. Choosing a suitable process plan is the top priority for improving gold extraction efficiency. Therefore, it is recommended to conduct ore dressing tests. Through experimental analysis, a suitable gold ore gravity separation method can be designed to achieve efficient recovery.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE