Gold flotation technology has been widely used in gold ore dressing plants, especially those containing sulfide. With the continuous development and utilization of rich gold mines, their resources have gradually become impoverished and complicated. In order to improve the recovery rate of gold flotation, reduce production costs and environmental impact, it is necessary to continuously optimize the flotation process and reagent system. The following will introduce the process flow, process optimization strategy and reagent selection method of gold flotation, flotation technology of difficult-to-select gold ores, etc., to help dressing plants improve gold ore dressing efficiency and reduce production costs.

Use the table of contents below to navigate through the guide:

01Gold flotation process

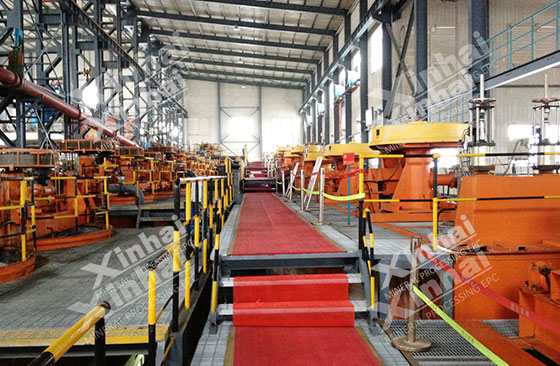

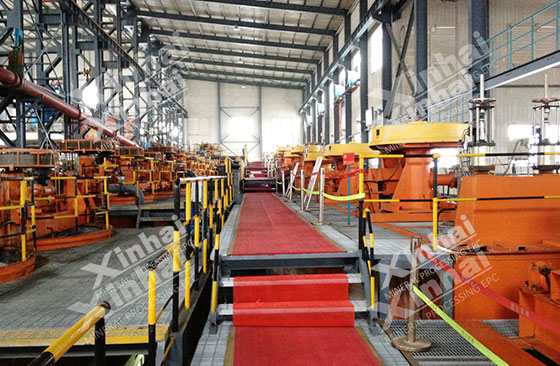

The gold flotation process generally includes crushing and grinding, slurry adjustment and flotation, and concentrate concentration and dehydration.

1. Crushing and grinding: Gold ore needs to go through coarse crushing, medium crushing and fine crushing processes during flotation to ensure that the minerals are fully separated from the monomers. After that, it enters the grinding stage, and the mineral fineness after grinding is required to reach 70%-90% at -200 mesh, which is convenient for improving the recovery efficiency of subsequent flotation.

2. Slurry adjustment and flotation: Add flotation agents to the slurry to adjust the pH value of the slurry and the surface properties of the minerals to improve the floatability of the minerals. After that, the slurry enters the flotation machine for roughing, concentrating and scavenging. Roughing can complete the recovery of most gold minerals and improve the enrichment of gold. The purpose of concentrating is to further improve the grade of gold concentrate and reduce impurity minerals. Scavenging can further recover the roughing tailings of gold ore and improve the total recovery rate.

3. Concentrate concentration and dehydration: The gold concentrate after flotation usually contains a lot of water and needs to be concentrated and filtered to finally obtain high-grade gold concentrate.

02Gold flotation process optimization strategy

Continuously optimizing the flotation process can improve the gold recovery rate and reduce the cost of mineral processing. Common flotation process optimization strategies include: optimizing the pH value of the pulp, adjusting the grinding fineness, optimizing the pulp concentration and adopting multi-stage flotation.

Optimization of pulp pH value: The pulp pH value during gold flotation generally needs to be controlled between 6-10, but it also needs to be adjusted according to the properties of the specific ore. Lime, sulfuric acid, sodium carbonate, etc. can be used to adjust the pulp pH value.

Adjustment of grinding fineness: Fine-grained gold ore flotation requires a finer grinding particle size, but it should be noted that too fine a particle size will increase reagent consumption and pulp viscosity. Therefore, the process of stage grinding and stage flotation can be used to improve the flotation recovery rate.

Optimization of pulp concentration: The pulp concentration of gold flotation generally needs to be controlled at 25%-40%. Too thin pulp will reduce the probability of contact between minerals and bubbles, while too thick pulp will cause the pulp fluidity to decrease.

Multi-stage flotation: Combine roughing, concentrating and scavenging processes to improve the recovery rate of gold ore. Multi-stage flotation can be used when dealing with gold ore with finer particle size and gold ore with more complex ore composition.

03Selection of gold flotation reagents

In the flotation process of gold ore, three types of collectors, frothers and depressants are needed. The use of a reasonable flotation reagent system will improve the flotation efficiency of gold ore.

Collector: The purpose is to enhance the hydrophobicity of gold minerals and improve the flotation recovery rate. Commonly used collectors are xanthate, black medicine, sulfur and nitrogen. When selecting a suitable collector, it is necessary to consider the type of gold ore and the occurrence state of gold.

Frother: Used to promote the generation of bubbles and improve the adhesion effect of minerals. Commonly used frothers include 2# oil, pine oil, etc. Selecting a suitable frother can optimize the foam structure and improve the grade of the concentrate.

Depressor: Used to suppress gangue minerals and improve the selectivity of gold ore. Commonly used gold flotation depressors include lime, copper sulfate, cyanide, etc. Appropriate adjustment of the dosage of depressors can reduce the floating of gangue minerals and improve the recovery rate.

04Difficult-to-treat gold ore flotation technology

Refractory gold ores usually refer to high-sulfur, high-arsenic, fine-grained gold ores, etc. Common treatment methods include: fine grinding technology, pre-oxidation treatment, and flotation + cyanidation combined process. Fine grinding technology can improve the dissociation degree of minerals and improve the floatability of gold ores. Pre-oxidation treatment technology can remove the film on the surface of sulfides and improve the flotation effect. Flotation + cyanidation combined process can improve the overall beneficiation efficiency.

The above is a simple introduction to gold flotation technology, optimization strategy, reagent selection and treatment methods for difficult-to-treat gold ores. Specific optimization measures are taken according to the characteristics of different ores to improve the flotation recovery rate of gold ores, reduce the beneficiation cost and improve the economic benefits of the beneficiation plant. Xinhai Mining can customize the design of gold flotation technology based on the characteristics of gold ores and the results of beneficiation tests to help customers achieve efficient production in beneficiation plants.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE