Gold, as a precious metal, has many advantages like stable chemical property, corrosion resistance and dis-oxidization.it can widely used in Jewelry, electronics, medical, aviation, construction and other industries. With the gradual depletion of gold ore resources, how to improve the utilization rate of gold ore resources and recover gold from low-grade gold ores has gradually attracted attention. To improve the recovery rate of gold mines, it is necessary to choose appropriate mineral processing methods. The following will introduce to you how to determine the beneficiation process of gold ore, and what factors should be paid attention to when using flotation method to process gold ore.

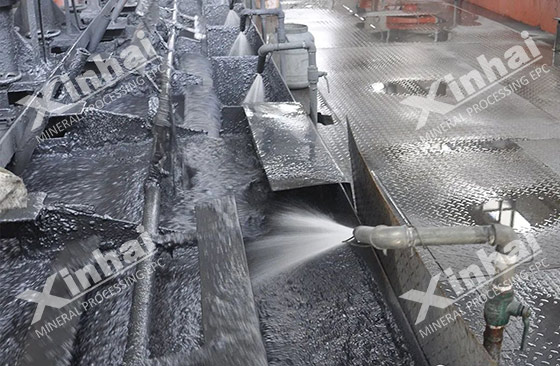

(Gold ore cyanidation process site)

Use the table of contents below to navigate through the guide:

01How to determine the beneficiation process of gold ore

When selecting a gold ore beneficiation process, the occurrence and distribution characteristics of gold and other valuable mineral components in the ore, the reserve scale of the deposit, and plant construction conditions are generally considered. The formulation of a reasonable mineral processing process also needs to be based on the mineral processing test results. When determining the gold ore beneficiation process, the following points should be noted:

(1) Recover large particles of gold in advance: Gold-bearing ores containing large particles of gold need to be set up a gravity separation or mercury amalgamation process to recover them as early as possible to prevent these gold particles from being lost or dispersed in equipment and pipelines during the separation process.

(2) Mud and sand separating: When there is gold-containing mud or mud containing almost no gold in the raw ore, flotation, gravity separation, cyanidation and other processes can be carried out according to the different gold-containing characteristics of the mud and ore sand to recover the gold. , thereby improving the gold recovery rate and increasing the processing capacity.

(3) Stage grinding and separation: When the gold particles present in the ore are unevenly distributed in thickness, the concentrator will choose stage grinding and separation processes to increase the gold recovery rate.

(4) Combined beneficiation and metallurgy process: The occurrence state and embedded particle size of gold particles in the ore are different, and the content of metal minerals that are symbiotic with gold is different. It is difficult to obtain a higher gold recovery rate using a single beneficiation method. Therefore, the combined process of dressing and smelting can be used to improve the utilization rate of gold mines and the gold recovery rate.

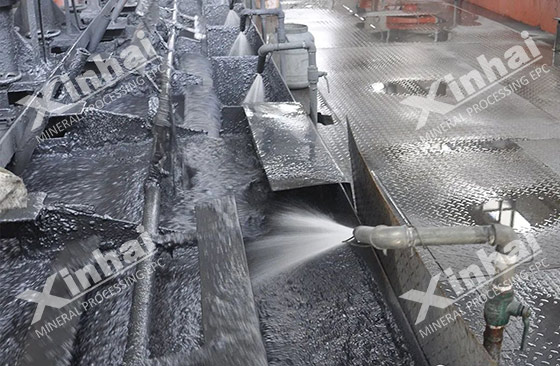

(Gold ore flotation processing site)

02Factors affecting gold ore flotation

The gold ore flotation process will be affected by many factors, including the particle size of the gold particles, the flotation pH value of the slurry, the concentration of the slurry, the content of the sludge, and the mineral composition.

Particle size of gold particles: Gold ore particles of different sizes have different floatability and can be basically divided into four categories: >0.8mm, no floatability; 0.4mm-0.8mm, can float about 5%; 0.25mm -0.4mm, 25% can be floated; <0.25mm, the flotation recovery rate can reach 96%. Generally, gold particles larger than 0.2mm need to be recovered by combining other beneficiation methods, such as gravity separation, mercury amalgamation, etc. The size of gold particles that can be flotated is closely related to the shape and surface state of the gold particles. Flat gold particles float easily, while spherical gold particles are less readable.

Flotation pH value of ore slurry: The pH value of gold ore flotation is generally 7-9, and soda is generally used as the medium adjuster. Lime will inhibit the flotation of gold-bearing pyrite and, to a certain extent, also affect the flotation of natural gold. During flotation, add activator to the slurry for vigorous stirring, maintain a high slurry liquid level in the flotation machine, and quickly scrape out the foam, which can improve the flotation efficiency of gold particles.

(flotation process)

Slurry concentration: Generally speaking, a high slurry concentration is beneficial to improving the recovery of coarse gold. But if it only contains flaky fine-grained gold, the solid-liquid ratio can also be very large.

Slime content: When the content of primary ore slime is high, the flotation process will be hindered, and talc, mica, carbonaceous materials and other scaly minerals in the ore will easily be flotated, resulting in the dilution of the concentrate. The surface of the gold particles will be covered by clayey sludge, making it difficult to float out the gold particles, resulting in a lower recovery rate. If the slime contains oxides such as iron and manganese, it will also increase the consumption of flotation reagents. Therefore, starch can be selected to inhibit the flotation of carbonaceous materials, talc, mica, etc. When suppressing and dispersing clayey slime, you need to pay attention to the control of the pH value of the medium, and you can use soda, sodium silicate, etc. to adjust it. If there are soluble oxides in the ore, soda needs to be added to precipitate the iron ions because the silicate gangue is activated by iron ions and floated out. A large excess of lime may inhibit the flotation of gold particles in pyrite.

(Gold ore)

Mineral composition: The flotation of gold-bearing ores is affected by the mineral composition. When there is free gold in the ore, it is necessary to use a stronger collector and increase the amount of foaming agent. Since the amount of free gold in the ore is small and its specific gravity is large, it is more difficult to float than sulfide. The use of thick slurry will achieve good flotation results. If the surface of the gold particles is covered with an oxide film, the action time of the agent needs to be extended. Copper sulfate and soda can be added to the grinding circuit to activate pyrite. When sweeping tailings, cationic collectors can be used to select quartz, and then the fine-grained gold can be dissociated through grinding.

The above content is an introduction to how to correctly choose the gold ore beneficiation process and the factors that affect gold ore flotation. In actual production, it is necessary to pay attention to the characteristics of the ore and production requirements to adjust the mineral processing process. Choosing an appropriate gold ore mineral processing process can further improve the recovery rate of gold and reduce the cost of gold mineral processing.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE