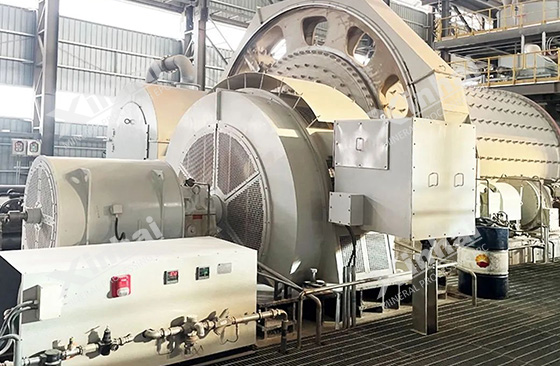

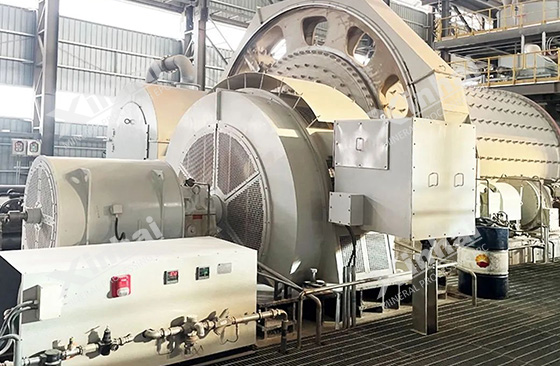

Grinding operation can separate useful minerals from gangue minerals during the mineral processing process, thereby improving the efficiency of subsequent mineral processing. However, there are many factors that affect the grinding process. In addition to the type of grinding equipment and the properties of the original ore, the operation of the grinding process is also an important influencing factor. The operating factors are mainly divided into grinding method, feeding speed, media addition system, rotation speed of grinding equipment, grinding concentration, classifier overflow concentration and fineness, ball-to-material ratio and return sand ratio. Therefore, formulating a reasonable grinding operation system, improving the operating level of technical personnel and adjusting the grinding operation parameters in time can improve the grinding efficiency and mineral processing indicators. The following article introduces the main operating factors that affect the efficiency of grinding operation to help you better understand the grinding process.

Use the table of contents below to navigate through the guide:

01Feeding speed of grinding operation

The feeding operation of grinding equipment can be controlled manually or automatically. The feeding amount during manual control is mainly controlled by the feeder and feeding belt scale under the ore bin. After adjusting the working parameters of the feeder, maintain a stable feeding amount of the grinding equipment. Wet grinding is more suitable for this feeding method, which is convenient for controlling the amount of water added to ensure the appropriate grinding concentration and fineness.

Ensure that the speed of the grinding equipment is within a certain range and increase the feeding speed appropriately. At this time, the material filling rate increases and the productivity of the grinding equipment is improved. If the material filling amount in the overflow ball mill exceeds its passing capacity, the steel balls and large pieces of ore will be discharged from the equipment, and the grid will also be blocked, so it is necessary to transport the ore. If the properties of the ore change, it is necessary to adjust the operating conditions and working conditions of the grinding work in time to adapt to the new process.

02Concentration control of grinding operation

If wet grinding is selected, the concentration of the slurry will affect the grinding time, productivity and power. Increasing the slurry concentration within a certain range can improve the productivity of the grinding equipment. Selecting a reasonable grinding concentration can ensure that the solid minerals move evenly on the surface of the grinding medium and facilitate the flow of materials from the feed end to the discharge end of the grinding equipment.

Too high a grinding concentration will increase the viscosity of the slurry, and the grinding medium will also be affected by buoyancy, resulting in a smaller effective density of grinding and a weakened impact force, which will greatly reduce the productivity of the grinding equipment. Fine-grained ore in a slurry with too low a concentration is easy to sink. When overflow-type grinding equipment is used, the product will become finer and it is easy to produce over-crushing problems. If the feed particle size is large and the circulating load is high, the grinding concentration should be controlled at around 80%.

03Product particle size control of grinding operation

The effect of grinding product particle size on the working efficiency of grinding equipment will change with the change of ore properties. The grinding efficiency of heterogeneous ores generally decreases with the increase of grinding fineness, because such ores will produce selective grinding when grinding. When grinding heterogeneous ores, the easy-to-grind components in the ore can be ground in the coarse grinding stage, and the difficult-to-grind particles in the material increase relatively during fine grinding, so the output is affected. The grinding efficiency of homogeneous ores sometimes increases as the particle size of the ore becomes finer. Because the average particle size of homogeneous ores becomes smaller and smaller in the later stage of grinding, the working efficiency of grinding equipment increases with time.

04Machine rotation speed of grinding operation

When the ball filling rate is kept within a certain range, the working efficiency of the grinding equipment will vary with the mill speed. The adaptability of the ore to the mill speed will vary with the type of ore. When the mill speed is slightly lower, it is difficult to achieve high productivity. From the above, it can be seen that it is necessary to adjust the appropriate mill speed to increase the output of the mill. However, the increase in grinding efficiency is small, and it will also increase energy consumption and liner wear. Rod mills need to reduce their speed appropriately according to structural requirements.

05Media addition system of grinding operation

During the operation of the mill, the consumption of steel balls or steel rods accounts for 65-90% of the total steel consumption of grinding, and the consumption of lining plates accounts for 10-15%. Therefore, it is shown that the material, size and addition system of the grinding media have an important impact on the grinding efficiency. Through long-term experiments and practices, balls and rods are often used as grinding media. The grinding media will gradually wear out with the beneficiation, and the size and weight of the media will continue to decrease. Therefore, the adaptability of the media to the ore particle size gradually deteriorates, and eventually leads to a decrease in grinding efficiency. The consumption of the media is related to the feed particle size, grindability, feed rate, slurry concentration and chemical properties (corrosiveness, etc.) of the ore being ground, the surface properties of the lining plate, and the size and material of the media.

The above are several factors that will affect the efficiency of grinding operation. The efficiency of grinding operations will also be affected by other factors. It is necessary to consider comprehensively and take corresponding measures to improve the efficiency of grinding. Xinhai Mining recommends customizing the design of the grinding process according to the properties of the ore and the production requirements of the ore dressing plant to improve the grinding efficiency while reducing the loss of useful ore.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE

.jpg)