Among the many methods of gold ore extraction, cyanidation gold extraction has become the main method of modern gold smelting due to its high efficiency and mature technical means. With the advancement of science and technology and the improvement of environmental protection requirements, different types of cyanidation gold extraction processes are also constantly developing and improving. This article will discuss in detail the process, characteristics and application scope of cyanidation carbon slurry gold extraction process, heap leaching gold extraction process, flotation concentrate cyanidation gold extraction process and resin gold extraction process, and analyze the application and advantages of these processes in actual production.

Use the table of contents below to navigate through the guide:

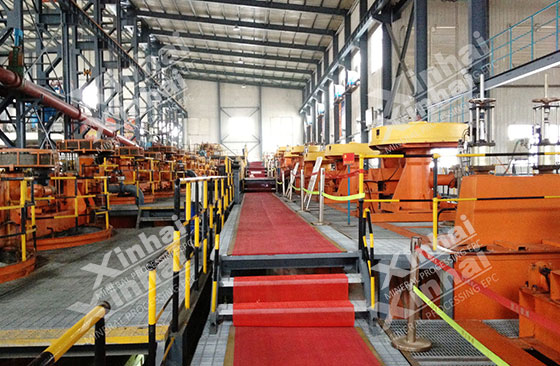

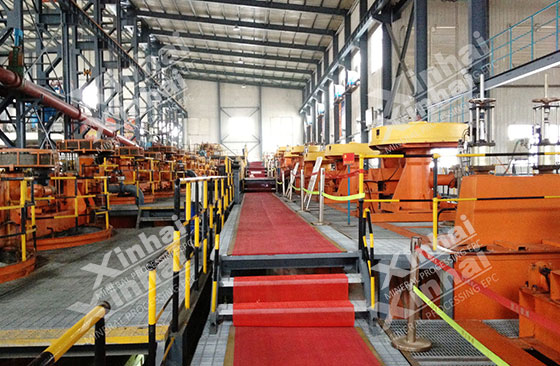

01Cyanide carbon slurry gold extraction process

The full mud cyanide carbon slurry method is a relatively advanced gold extraction process, which mainly has the following five steps:

① Use a 0.6mm screening machine to pre-screen the ore pulp

② Use activated carbon to adsorb the dissolved gold

③ Use a 0.85mm screening machine to separate the gold-loaded carbon

④ Desorb gold from the gold-loaded carbon

⑤Use electrolysis to recover gold from the desorbed gold-containing precious liquid. The desorbed carbon can be regenerated to remove impurities.

The carbon slurry method has many advantages, such as no solid-liquid separation, elimination of operations such as concentration filtration and zinc powder replacement, saving a lot of infrastructure costs such as plant construction and equipment purchase, and low production costs. This gold extraction process is more suitable for processing ores that are difficult to filter and concentrate.

02Heap leaching gold extraction process

Heap leaching gold extraction process has the advantages of short production process, easy to master technology, low investment, quick effect, large or small production scale, high or low mechanical degree, etc. It is a very flexible means of gold extraction, which can be applied to those ores with severe weathering and oxidation, especially suitable for low-grade impregnation deposits. There are two types of heap leaching methods used in industry: one is to directly leach the mined ore, which takes a long time to leach, and the other is to leach the ore after crushing, which has a short leaching cycle. The key factors affecting the leaching process are solution permeability, transportation and recovery.

03Flotation concentrate cyanidation gold extraction process

The flotation-concentrate cyanidation gold extraction process is generally used to treat gold-containing sulfide primary ores, with low mud content, easy flotation enrichment, and high recovery rate. The characteristics of this process: after flotation enrichment, the gold grade of the concentrate is improved, the amount of ore entering the cyanidation gold extraction process is reduced, and the consumption of cyanide will also be reduced. This process has little pollution to the environment and saves infrastructure investment costs and production costs.

04Resin gold extraction process

Compared with the carbon slurry method, the resin slurry method has a faster gold adsorption rate and a saturated gold loading capacity than activated carbon, and it is easier to desorb gold from resin than from activated carbon. Resin is stronger than activated carbon and is not easily abraded. It is not contaminated by organic matter and does not require regular heat treatment to restore activity. Therefore, it is more economically superior to activated carbon. When treating gold-bearing pyrite, organic ore or extremely fine gold ore, the resin slurry gold extraction process can increase the gold leaching rate.

In summary, the cyanide gold extraction process covers multiple steps from ore pretreatment to the final recovery of gold, and each process has its unique advantages and applicable conditions. In actual production, choosing a suitable gold extraction process can not only effectively improve the gold recovery rate, but also reduce production costs and environmental impact. With the continuous advancement of technology, the cyanide gold extraction process will continue to be optimized and innovated in the future, further promoting the development of gold smelting technology. Reasonable selection of the process in combination with the properties of the ore and the scale of production will help to maximize the utilization of gold resources.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE