Since it was found that cyanidation solution could dissolve gold in 1887, the cyanide leaching process has been put into production for nearly a hundred years. Nowadays, the cyanide leaching process is still the main gold processing method because of its high recovery rate of gold, strong ore adaptability and ability to on-site gold production.

Gold extraction by cyanide leaching process is divided into two steps: cyanidation leaching and deposition. The specific leaching processes include the percolation cyanide leaching process, agitation cyanide leaching process and heap leaching process.

Among them, the percolation cyanide leaching process and agitation cyanide leaching process are the traditional leaching processes, while the heap leaching process is a new technology that emerged in the last 20 years, which is mainly used to treat low-grade oxidized gold ore.

Use the table of contents below to navigate through the guide:

01Percolation cyanide leaching process

The cyanidation solution penetrates through the ore layer, thus leaching the gold from the ore. This leaching process is suitable for placer and loose porous materials.

The main equipment used in the percolation cyanide leaching process is the leaching tank, which is round, rectangular or square. The diameter or side length of the leaching tank is generally 5-12 meters, the height is generally 2-2.5 meters, and the volume is generally 50-150 tons.

02Agitation cyanide leaching process

After the grinding and classifying, the ore pulp is placed in the leaching tank, and the cyanide solution is added into the pulp, and then the leaching is carried out after aeration and stirring. The agitation cyanide leaching process is mainly used for materials whose particle size is less than 0.3~0.4 mm. The main equipment used in this leaching process is the leaching tank. According to the leaching method, it can be divided into continuous agitation cyanide leaching process and intermittent agitation cyanide leaching process.

• Intermittent agitation cyanide leaching process

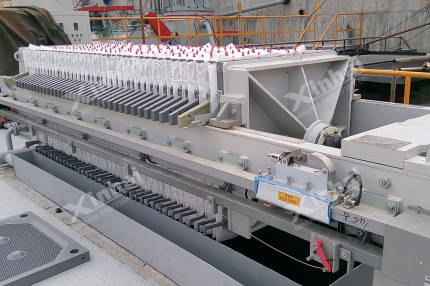

The slurry is put into the several stirred leaching tanks in the parallel working state and enters the cyanide leaching. After the completion of gold leaching, the slurry is put into the storage tank for storage, then filtering and washing in batches.

• Continuous agitation cyanide leaching process

Generally, this leaching process is carried out continuously in a series of 3-6 leaching tanks. After the slurry enters the first leaching tank and is cyanided, it flows into the second leaching tank and the third leaching tank successively. It keeps the continued cyanide leaching until the last leaching tank.

Compared with the intermittent agitation cyanide leaching process, the continuous agitation cyanide leaching process has the following advantages:

Achieve the automation of the production process;

Save the loading and unloading time, improve the production capacity of the equipment;

No storage tank, save the construction area and reduce the production costs.

03Heap leaching process

The heap leaching process means that the ore is broken into 3~10 mm blocks, and stacked on the impermeable bottom mat, and then the cyanide solution is sprayed from the top of the pile to dissolve the gold in the ore.

The heap leaching process is considered the most desirable gold processing method of low-grade ores because of its simple process flow and it does not require the large infrastructure projects or excessive production equipment, thus greatly reducing the production costs.

Before selecting the specific cyanide leaching process, it is suggested that each mine owner should do the mineral processing test in advance, determine the appropriate cyanidation leaching process according to the results of the mineral processing test, and at the same time, make choices based on the size of the concentrator, conditions of the concentrator, investment cost and other factors, so as to finally achieve the optimal balance between technical and economic indicators.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE