The slurry concentration refers to the content of the solid material in the slurry, usually represented by wg which is used to define the ratio of liquid to solid or solid mass fraction. The slurry concentration is one of the most important factors which affect mining hematite ore. It will affect the charging degree of hematite ore slurry, the residence time in of hematite ore slurry in the flotation cell, reagent system and the adhesion process of bubble-particle. The article is going to introduce the effect of slurry concentration on mining hematite ore.

(1) The inflatable performance of flotation cell changes with the hematite ore slurry concentration. Whether the slurry is too thick or too thin will make the inflation situation worse, thus affecting the hematite ore flotation recovery rate and flotation time.

(2) Under the same dosage, if the slurry density increases, the reagent concentration also will increases, which will be conducive to mining hematite ore so as to reduce the drug dosage and the reagent cost.

(3) With the increase of slurry concentration, the residence time of the slurry in flotation cell will be prolonged and this is conducive to the improvement of recovery rate. If the flotation time constant, with the increase of the slurry concentration, the productivity of mining hematite ore increases.

(4) In a certain range, with the increase of slurry concentration,buoyant force lift, this is conducive to the flotation of coarse hematite; but too thin will deteriorate the aeration conditions. For fine particle flotation, with the increase of slurry concentration, fine-grained hydrophilic hematite will affect the reverse flotation.

In short, increasing slurry density is beneficial to hematite reverse flotation, and the water and power consumption of per ton of material is less. General principles of hematite slurry concentration are a coarse grain with high concentration, fine with low concentration; roughing by high concentration, featured by low concentration. The range of hematite concentration of reverse flotation is generally 22~40%.

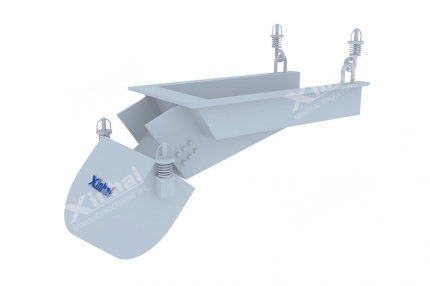

Xinhai is a well-known manufacturer of flotation cell, our flotation cell has excellent flotation index, stable production, low energy consumption, wear resistance, low cost, easy installation, easy maintenance, we will choose the most suitable flotation cell and design the best flotation conditions for you base on your needed, so that achieve the most benefit for you.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE