With the development of new energy vehicles, the demand for lithium resources at home and abroad is increasing, which also causes the supply gap of lithium resources. About 35% of the world's lithium resources come from lithium-rich minerals and clay, so lithium can be extracted from lithium-rich minerals to meet the needs of the market. Its main beneficiation technology mainly includes three kinds, respectively: gravity separation, magnetic separation and flotation separation. In general, redressing is mainly used to remove crude gangue or for lithium extraction of high grade ore. Flotation is mainly used to purify fine-grained materials. Magnetic separation method can be used to remove iron-containing gangue in lithium-rich minerals, which can further improve the concentrate grade.

Because of the different types of lithium-rich ore, the mineral processing process used is also different. The following will introduce three lithium-rich mineral lithium extraction processes, spodumene, lithium micite and lithium phosphate ite.

Use the table of contents below to navigate through the guide:

01Spodumene lithium extraction process

As an important raw material for lithium extraction, the methods for extracting lithium from spodumene mainly include flotation and chemical leaching.

Spodumene flotation method: The flotation method has wide applicability and is widely used in the purification of spodumene with industrial value. However, the flotation agent is one of the important factors affecting the flotation effect of spodumene, so it can be replaced with an efficient and environmentally friendly collector. For example, sodium oleate / tributyltetradecyl phosphorus chloride can be used to isolate spodumene from flotation in feldspar. It is a new type of mixed anion/cation collector, which can get better flotation separation effect. In addition, adding a small amount of cationic collector dodecylamine hydrochloride (DDA) during flotation can significantly improve the effect of anionic collector sodium oleate separating spodumene from feldspar.

Spodumene chemical leaching method: chemical leaching is one of the commonly used methods for spodumene purification, but pre-activation treatment of the ore is required. Among them, destroying the aluminum silicate structure is the key to lithium extraction by chemical leaching of spodumene. Since spodumene is similar to illite, the Bayer process can be introduced to process natural α-spodumene. The ore decomposes under alkaline conditions. Adding calcium oxide and increasing the temperature can accelerate the decomposition of spodumene. After optimization, the leaching rate of lithium can be increased to about 93%.

02Lepidolite lithium extraction process

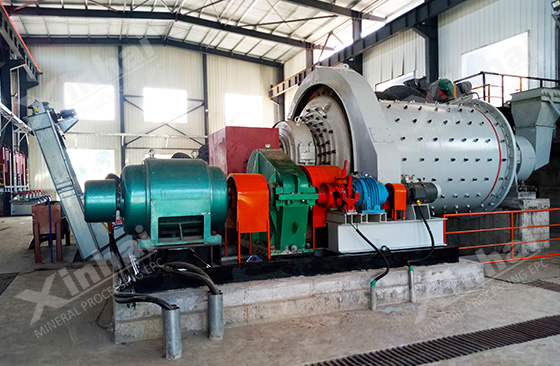

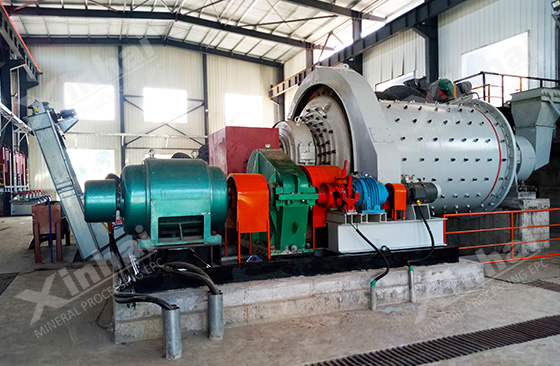

Chemical leaching is one of the main methods for extracting lithium from lepidolite ore. The use of different activators can result in different leaching rates. For example, when potassium sulfate is used as an activator, the structure of lepidolite does not change significantly, and the leaching rate of lithium can reach 98.7%. If potassium salt is used as the activator, combined with ball mill grinding, the leaching rate of lepidolite can reach 99.1%. Therefore, it is necessary to choose the appropriate type of activator and the mass ratio to the concentrate. At the same time, the rotational speed of the ball mill, the grinding time, the reaction temperature and the stirring speed are all factors that affect the lepidolite chemical leaching effect.

03Lithium extraction process of lithium phosphorite aluminum

Lithium extraction from lithium phosphoenite generally refers to a mineral rich in lithium and phosphate, which is firstly obtained by flotation to obtain lithium phosphate concentrate, and then enters the mill for grinding pretreatment, and is leached with concentrated sulfuric acid to make lithium, Aluminum is converted into soluble sulfate, and fluoride and phosphate are extracted to obtain an enriched leachate. Acidic impurities can be precipitated by adding limestone, lime, monovalent carbonate or hydroxide to remove impurities in the lithium-containing filtrate, and recover lithium as a lithium-containing salt product.

The above is a brief introduction of the lithium extraction process of spodumene, lithium-micite and lithium phosphate aluminum stone. Because there are great differences in ore types and properties of different deposits, it is necessary to conduct beneficiation test analysis to determine the appropriate beneficiation process scheme. Xinhai can provide you with one-stop mineral processing general contracting service (EPC+M+O), advanced, efficient and energy-saving lithium ore processing equipment, if there is demand, welcome to consult us.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE