Phosphate rock is a finite natural resource whose production and grade are gradually decreasing. Since the mining and processing of phosphate rock involves certain costs and environmental impacts, the limited resources make beneficiation a necessary means to extract more high-grade phosphate minerals. Flotation is a commonly used phosphate ore beneficiation technology. However, there are many influencing factors in the beneficiation process. Understanding the factors that affect the phosphate flotation effect is an effective way to improve the beneficiation efficiency and achieve the target. The following will introduce the factors affecting phosphate flotation from the three aspects of ore properties, pulp pH value and beneficiation reagents.

Use the table of contents below to navigate through the guide:

01Ore Properties on Phosphate Flotation

Particle Size Distribution: The particle size distribution of ore can affect the flotation process by affecting the efficiency of collision and attachment between particles and air bubbles. Fine particles may have difficulty attaching to air bubbles, reducing concentrates recovery rate.

Mineral composition: The different types and proportions of minerals present in the ore, such as apatite (phosphate mineral), gangue minerals (such as silicates, carbonates, etc.), and impurities, will affect the selection of appropriate flotation reagents and strategy. Different minerals may respond differently to flotation reagents, resulting in different separation efficiencies.

Surface properties: The surface properties of minerals, including their hydrophilicity (ability to interact with air bubbles) or hydrophobicity (repellency to water), affect their attachment to air bubbles during flotation. Hydrophilic minerals tend to attach to the air bubbles and are recovered in a selective manner.

02Pulp pH Value on Phosphate Rock Flotation

The pH value plays an important role in affecting the flotation process of phosphate rock. The pH of the flotation slurry affects the surface charge of minerals, the solubility of reagents, and the stability of gas bubbles. Here's how the pH affects the flotation process:

Surface charge: pH affects the surface charge of minerals. Many minerals have pH-dependent surface charges due to the dissociation of surface functional groups. Changing the pH can alter the electrical charge, thereby affecting the interaction between the mineral and the flotation reagent.

Reagent Solubility: The solubility of flotation reagents such as collectors and inhibitors will vary with pH. Maintaining the proper pH helps maintain the effectiveness of the reagents and keeps them in solution for optimal flotation performance.

Bubble Stability: pH affects the stability of the bubbles generated during the flotation process. Maintaining the proper pH range helps maintain stable air bubbles, which in turn aids in the separation of mineral particles from the slurry.

03Ore dressing reagents on phosphate rock flotation

The selection of beneficiation agents has an important impact on the flotation process, and its type and dosage depend on the mineral composition of the ore and the desired separation effect. Here's how chemicals affect the flotation process:

Dosage control: The amount of reagent added to the flotation slurry must be precisely controlled. Too little dose can lead to poor mineral recovery, while too much dose can lead to increased costs and environmental concerns.

Drug combination: The combination of different drugs and their dosage is a complex optimization process. Interactions between various reagents may affect flotation performance and separation selectivity.

In the flotation process of phosphate rock, agents such as collectors, inhibitors, activators and pH regulators are usually used. The choice of agent depends on the type of phosphate mineral. For example, common phosphate ore collectors include fatty acids, amines and quaternary ammonium compounds. In phosphate rock flotation, inhibitors may be used to suppress gangue minerals or other minerals that do not require flotation. Commonly used inhibitors include sodium silicate and sodium carbonate. Activators are used to selectively activate valuable minerals that may not be easily floatable. In phosphate rock flotation, activators can be used to improve the flotation performance of phosphate minerals.

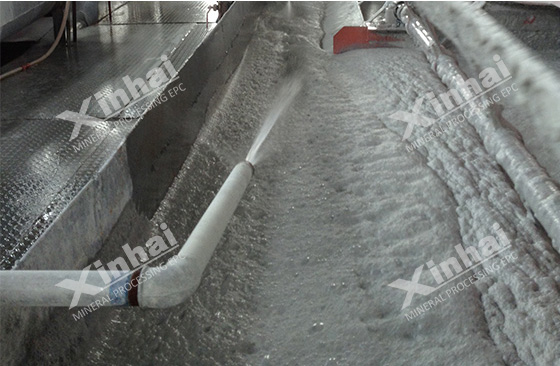

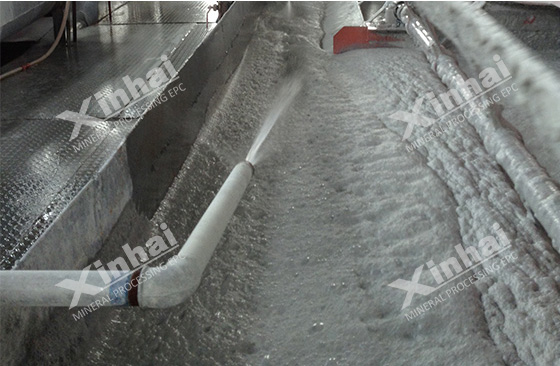

In order to optimize the phosphate flotation process, it is necessary to understand these factors and adjust the process conditions, reagent selection and equipment configuration according to the situation. Pilot testing and ongoing monitoring can help fine-tune the process to achieve the desired separation. Efficient phosphate flotation process is based on beneficiation test results and production requirements. Xinhai Mining suggested to conduct phosphate ore beneficiation test, and provide customized phosphate ore beneficiation plan according to ore properties and customer needs, so as to improve the beneficiation efficiency of phosphate ore.

marketing@ytxinhai.com

marketing@ytxinhai.com  0086 13810327080

0086 13810327080

CHAT

CHAT MESSAGE

MESSAGE